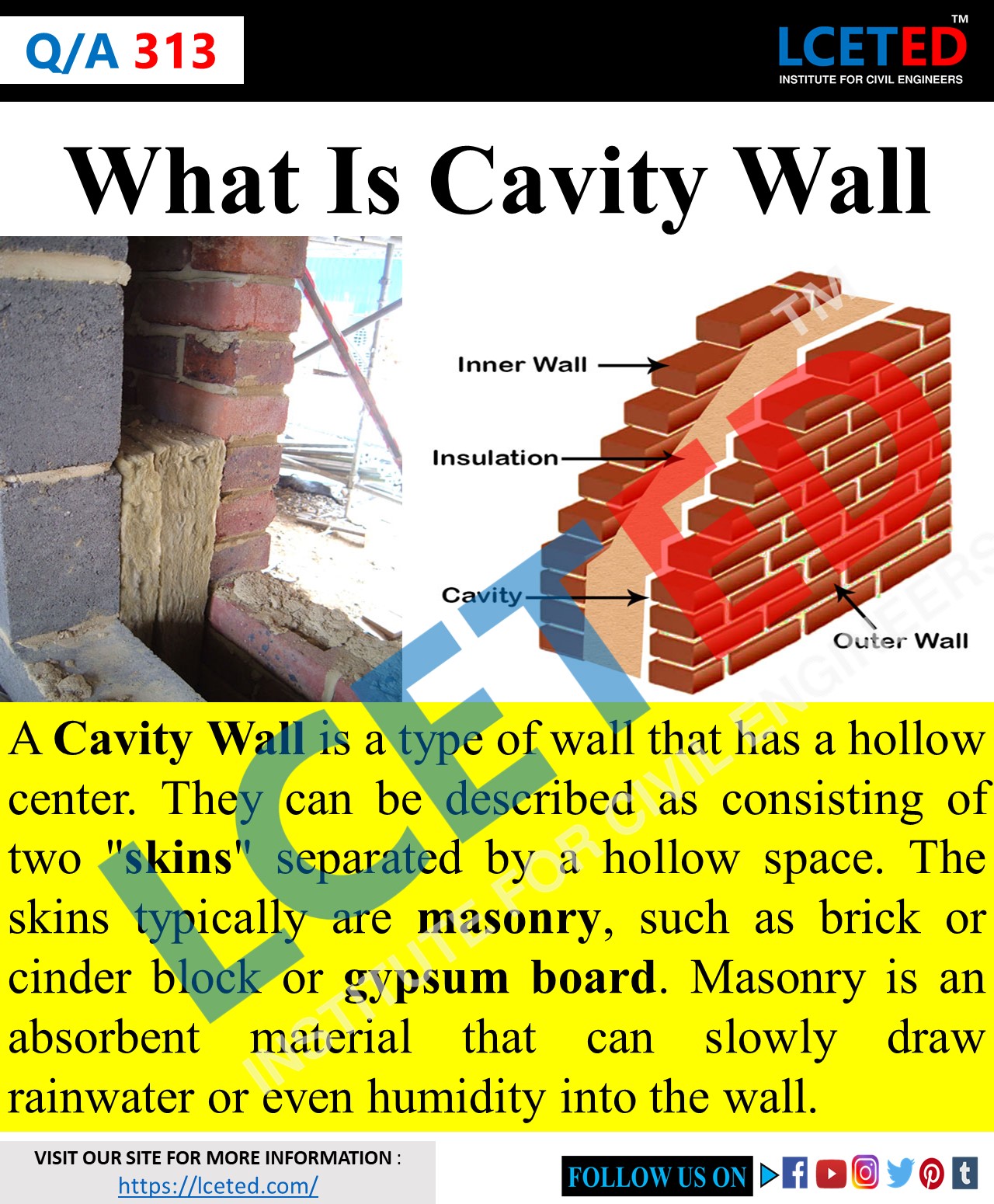

What Is Cavity Wall?

A Cavity Wall is a type of wall that has a hollow centre. They can be described as consisting of two "skins" separated by a hollow space. The skins typically are masonries, such as bricks or blocks or gypsum board. Masonry is an absorbent material that can slowly draw rainwater or even humidity into the wall.

Details Of Cavity Wall

Constructions

Is Both Side Skins Of Cavity

Wall Should Equal?

Both side skins of

cavity wall may be of equal thickness if it is a non-load-bearing wall or the

inner skin wall may be thicker than the outer skin, to meet structural

requirements.

How The Two Skins Of Cavity Wall Connected?

The two skins of the wall can be

connected to each other by metal pins or a connecting brick at horizontal intervals of about 1000mm to 1200mm and vertical the interval of 300 to 450mm.

How Can Space

Between Two Skins Of Cavity Wall Filled?

The cavity between the two skins

should not less than 50 mm and not

more than 75 mm. The space between

the skins is either left as hallow or filled with Rock Wool, Glass Wool, Polystyrene Bead and Cavity Foam Insulation

What Are The Advantages & Disadvantages Of Cavity Walls

Advantages Of Cavity Walls

1. Cavity walls have good fire-resistant

2. Cavity wall can reduce the moisture condensation

risk

3.

The wall can reduce the cost of cooling the building

4.

It has good protection against efflorescence.

5.

It gives good sound insulation property.

Disadvantages Of Cavity Walls

1. Needs

highly skilled labourers and mason

2. Needs

high supervision during the process

3. Carpet

area may decreases

4. Main the problem of cavity walls is wall ties rusting. (life period of ties 10 to 15

years)

Special Points to be Observed in Cavity Wall

Construction

(i) The cavity should

extend to 15 cm below the damp-proof course level.

(ii) Below the ground

level, the walls are built solid, or preferably the cavity should be filled up

to 15 cm above the damp-proof course with fine concrete.

(iii) Under no

circumstances, should the DPC be laid to span one leaf only. It should cover

both leaves of the wall.

(iv) The upper part of the

wall where it ends should also be built solid for two or three courses below

the wall plate or roofline, to stiffen the head of the wall and distribute the

load over both leaves.

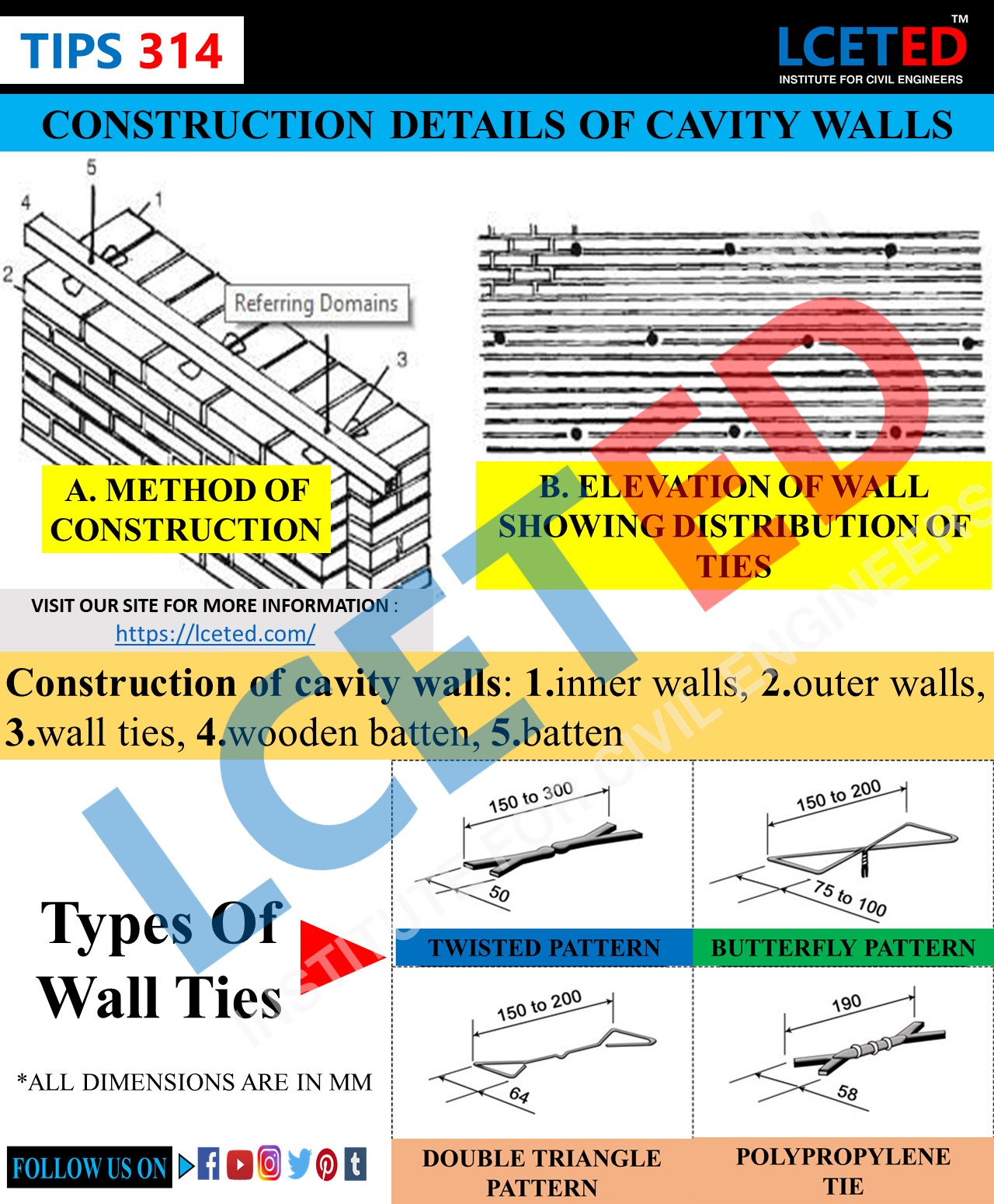

(v) The wall ties must be

kept free from mortar droppings by means of a timber batten suspended in the

cavity and raised as the work proceeds during its construction. Some bricks may

be temporarily left out at the ground floor level to form openings to permit

the bottom of the cavity to be cleared of mortar droppings at the end of each

day's work.

(vi) In exposed positions,

it is desirable to leave a few vertical joints in the outer leaf open, at the

bottom of the cavity to permit water to drain away.

(vii) A certain amount of

ventilation to the cavity is desirable to prevent stagnation of air and

excessive humidity. It can be provided by vents, say 150 x 75 mm (6" x

3") at intervals, near the base and top of the wall, by leaving a few

joints open.

(viii) The cavity walls

should not be built solid at the jambs [the sides of door and window openings

(see Fig. 1.2)] unless a vertical "damp-proof course" is inserted to

prevent water from driving to the inner face. Thus solid jambs without DPC are only

permissible in fairly sheltered sites and where the wall surface is roughcast.

(ix) A lead, galvanised

iron or other suitable material made to form a trough or gutter, may be placed

in the cavity above all openings for exposed doors and windows to collect water

which may drive through the outer leaf.

(x) The cavity wall should

not be built solid below window sills also and a damp-proof course is desirable

at this point also.

HOPE YOU LIKE THIS ARTICLE SUBSCRIBE US OR CLICK THE BELL ICON FOR INSTANT NOTIFICATION |

In a world where digital interaction is constant, enhancing your device with high-quality wallpapers is one of the simplest yet most powerful ways to refresh your environment and express your identity. With endless designs to explore, you can reinvent your screen at any moment—transforming ordinary displays into captivating pieces of art. Whether you want inspiration, calmness, or a burst of creativity, the right wallpaper can instantly elevate your digital space and make every interaction feel more meaningful

ReplyDeletehttps://colornjoy.com/blogs/hello-kitty-wallpapers/aesthetic-hello-kitty-pfp-download-8gf5r10b7

https://colornjoy.com/blogs/pink-wallpapers-1/hello-kitty-pink-pfp-free-3wz5v84t1

https://colornjoy.com/blogs/hello-kitty-wallpapers/4k-background-cute-hello-kitty-wallpaper-download-6ap4t38h7

What sets contemporary art bottles and tumblers apart is their ability to turn the everyday into something extraordinary. They make hydration an experience that combines creativity, practicality, and personal style. Each piece not only serves its functional purpose but also provides aesthetic pleasure and a subtle emotional connection. This harmony of form and function elevates them beyond ordinary drinkware, establishing them as essential lifestyle accessories rather than just utilitarian items.

ReplyDeletehttps://colornjoy.com/products/spooky-doll-halloween-water-bottle-coloring-activity

https://colornjoy.com/products/dragon-adventure-water-bottle-kids-coloring

https://colornjoy.com/products/space-crew-coloring-water-bottle-kids-educational-toy

https://colornjoy.com/products/hedgehog-explorer-coloring-water-bottle-outdoor-toys