FIRST

CHOOSE BETWEEN THESE OPTIONS THEN START TO READ THE ARTICLE, WE EXPLAINED ABOUT

DEVELOPMENT LENGTH

WHAT IS DEVELOPMENT LENGTH?

It is Used at

BEAM-COLUMN JOINT

OR

COLUMN-FOOTING JOINT.

To develop a safe bond between the bar surface & the concrete so

that no failure due to slippage of bar occurs during the ultimate load

conditions.

Also, the extra length of the bar provided as development length is

responsible for transferring the stresses developed in any section to the

adjoining sections (such as at column beam junction the extra length of bars

provided from beam to column).

GUIDELINES FOR DEVELOPMENT

LENGTH DESIGN | REQUIREMENTS FOR DEVELOPMENT LENGTH DESIGN | LCETED

DEVELOP

LENGTH CALCULATIONS

For

+ve moment, 𝐿𝑑 =

47𝜙 (for M 20 and Fe

415)

For

+ve moment, 𝐿𝑑 =

57𝜙 (for M 20 and Fe

500)

For

– ve moment, 𝐿𝑑 = 𝐿/4

At least 1/3 of the +ve moment steel in S.S. beam and 1/4

of the +ve moment steel in continuous beam extends to support for a distance of

𝐿𝑑/3

If

total bars = 6, therefore 1/3 × 6 ≥ 2 (means 2 bars will

curtail and 4 go to support)

For a cantilever beam, available development length is nearly

equal to span length

For

continuous beam, available length = 𝑥𝑜 + D

or 12𝜙 or 𝐿/16 (whichever is

greater); 𝑥𝑜 =

length of –ve moment region, i.e., the distance between the point of contra flexure

from the centre of support.

In practice, usually, bars are provided for a length = 𝐿/4 from the centre of

support which then becomes the available length.

At least 1/3 of the -ve steel should have an embedment

length beyond the point of inflexion not less than

D or 12𝜙 or

𝐿/16 (whichever is

greater)

Top steel in beams is to be spliced at mid-span (for 𝐿𝑑)

and bottom bars to be spliced near support after (2𝐷 𝑜𝑟 𝐿/4).

Lap of bottom steel in slab is to be done near support

(if required)

At the junction of beam/shear wall, 𝐿𝑑 =

1.5𝐿𝑑

If bars are provided in 2 layers, it is better to

curtail bars of layer 2 only.

For beams of up to 2.5 m, no need of curtailment of top

and bottom bars, i.e., all bars are ALTH (all through).

Curtailment:

TPC from centre of support,

𝑁′=no

of bars to be curtailed

𝑁𝑚𝑎𝑥 =

no of bars at mid-span

The actual point of cut off (APC) from the centre of support= 𝑥1 − 𝑒𝑓𝑓 𝑑𝑒𝑝𝑡ℎ(𝑑)

CALCULATION OF

DEVELOPMENT LENGTH

As per the Indian Standard – IS 456: 2000, clause 26.2.1 the

development length Ld is given the following expression;

Where,

Ø = nominal dia of reinforcement bar

σs = Stress in the bar at the section considered at design load

τbd

= Design bond stress

The formula given above is used to calculate

the required development length in mm for any bar dia, the same formula is used

for the limit state mode and the working pressure system. The only change in

the calculation in both methods is due to the different value of the design

bond stress; The values of the design bond for the limit level and working

pressure are as follows;

|

DESIGN BOND STRESS IN LIMIT STATE METHOD |

||||||

|

Concrete Grade |

M20 |

M25 |

M30 |

M35 |

M40

& Above |

|

|

Design Bond Stress (τbd, N/mm2) |

1.2 |

1.4 |

1.5 |

1.7 |

1.9 |

For

Plain Bars in Tension |

|

1.92 |

2.24 |

2.4 |

2.72 |

3.04 |

For

deformed bars in tension |

|

**Note: For bars in compression 1.25 times the above-given values shall

be used.

|

DESIGN BOND STRESS

IN WORKING STRESS METHOD |

||||||||

|

Concrete Grade |

M20 |

M25 |

M30 |

M35 |

M40 |

M45 |

M50 |

|

|

Design Bond Stress (τbd, N/mm2) |

0.8 |

0.9 |

1.0 |

1.1 |

1.2 |

1.3 |

1.4 |

For Plain Bars in Tension |

|

1.28 |

1.44 |

1.6 |

1.76 |

1.92 |

2.08 |

2.24 |

For deformed bars in tension |

|

**Note: For bars in compression 1.25 times the

above given values shall be used.

How to calculate the development length for different grades of concrete as per IS 456?

Example - 1

Given data

Calculate the development length for rebar in tension, by limit state

method for the below-given data.

Grade of concrete = M25

Reinforcement bar = Fe500 (σs = 500 )

Diameter of bar = 20mm. (∅ )

The development length Ld = ∅ × σs ÷ 4 ×

τbd

Ld = 20 × 500 ÷ 4 × 2.24

(τbd = 2.24 N/mm2 for M25 in tension, for the limit state. From the

above-given table,)

= 10000 ÷ 8.96

Ld = 1116.07mm.

Example - 2:

Given

data

Calculate the development length for rebar in

compression, by working stress method for the below-given data.

Grade of concrete = M30

Reinforcement bar = Fe415 (σs = 415 )

Diameter of bar = 16mm. (∅ )

The development length Ld = ∅ × σs ÷ 4 × τbd

Ld = 16 × 415 ÷ 4 × 1.6

(τbd = 1.6 N/mm2 for M25 in compression, for

the working stress method. From the above-given table,)

= 6640 ÷ 6.4

Ld = 1037.5mm.

As per thumb rule development length is 45d-55d.normally we take 50d.which means

for 16 mm dia bar development length would be 50*16 = 800mm=2.6 feet

FAQ ON DEVELOPMENT LENGTH

What

will happen if we don't provide development length?

REASONS

FOR PROVIDING DEVELOPMENT LENGTH

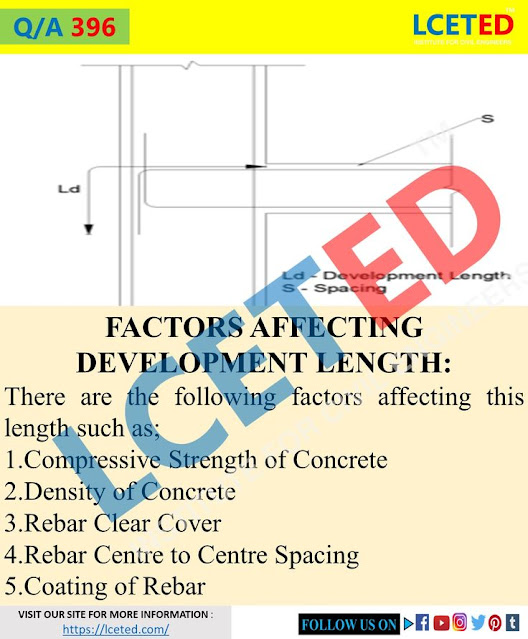

FACTORS AFFECTING DEVELOPMENT LENGTH?

What

will happen if we don't provide development length?

If you find

This information helpful, please share it.

Thanks! For reading the article.

No comments:

Post a Comment