• Practically, it is a

common practice that if 𝐿/𝐵 > 1.5, design it

one way slab.

• If 𝐿𝑥

> 3 𝑚: it is advisable to

provide a two-way slab.

• Common depth of slabs =

5”, 6” (125 mm, 150 mm); max=200 mm (for load = 5 𝑘𝑁/𝑚𝑚2

).

L/D

ratios:

• One way S.S slab 𝐿/𝐷 = 20 × 𝑚. 𝑓 = 20 × 1.4 = 28 𝑓𝑜𝑟 𝑝𝑡 =

0.3%, 𝑚. 𝑓 = 1.4) . Adopt 𝐿 𝐷 = 25.

• One way continuous, above value (25) shall be

multiplied by 26/20 = 1.3 = 25 × 1.3 = 32.5. Adopt 𝐿/𝐷 = 32.

• Two way S.S slab 𝐿/𝐷 = 28 (for 𝐿𝑥 ≤

3.5𝑚 𝑎𝑛𝑑 𝐿. 𝐿 ≤ 3 𝑘𝑁 𝑚2 )

• Two way continuous slab 𝐿/𝐷 = 32 (for two-way

slab, shorter of the two spans be used to calculate 𝐿/𝐷 ratio

• Common diameter of bars =

8, 10, 12 mm. (dia. ≯ 𝐷/8)

• Approx. area of main

steel in slabs, 𝐴𝑠𝑡 = 𝑀𝑢/0.8𝑑.𝑓𝑦 (𝑀𝑢 =

0.138𝑓𝑐𝑘𝑏𝑑2 )

Theoretically,

calculated 𝐴𝑠𝑡 is provided in the middle strip and min. 𝐴𝑠𝑡 is provided in edge strip. In practice,

bars are uniformly provided spaced throughout spans in both directions.

• Assume 𝐴𝑠𝑡 =

0.3 − 0.45% (one way slab)

• Assume 𝐴𝑠𝑡 =

0.2 − 0.3% (two way slab)

• Assume 𝐴𝑠𝑡 =

0.5% (one way continuous)

• Maximum area of main

steel in slab = 4% 𝑜𝑓 𝑏𝐷

(As per ACI).

• All top reinforcement of

slabs shall continue up to 𝐿/3

of span at both sides of C/L of wall or Beam.

• Corners free to lift:

cast over walls and no parapet above

• Roof slab with corner

held down is achieved by 230 mm parapet wall, 600 mm high and 2 m length on

either side of the corner

• Area of distribution steel = 0.12% 𝑜𝑓 𝑏𝐷

(For floor slab)

• Area of distribution

steel = 0.24% 𝑜𝑓 𝑏𝐷

(For roof slab)

• Short span bars are

provided in the bottom layer.

• If two different dia.

bars are used, provide larger dia. bars at the bottom layer.

• Due to openings in slabs,

area of steel interrupted be replaced by an equivalent amount, half of which

should be placed along each edge of the opening.

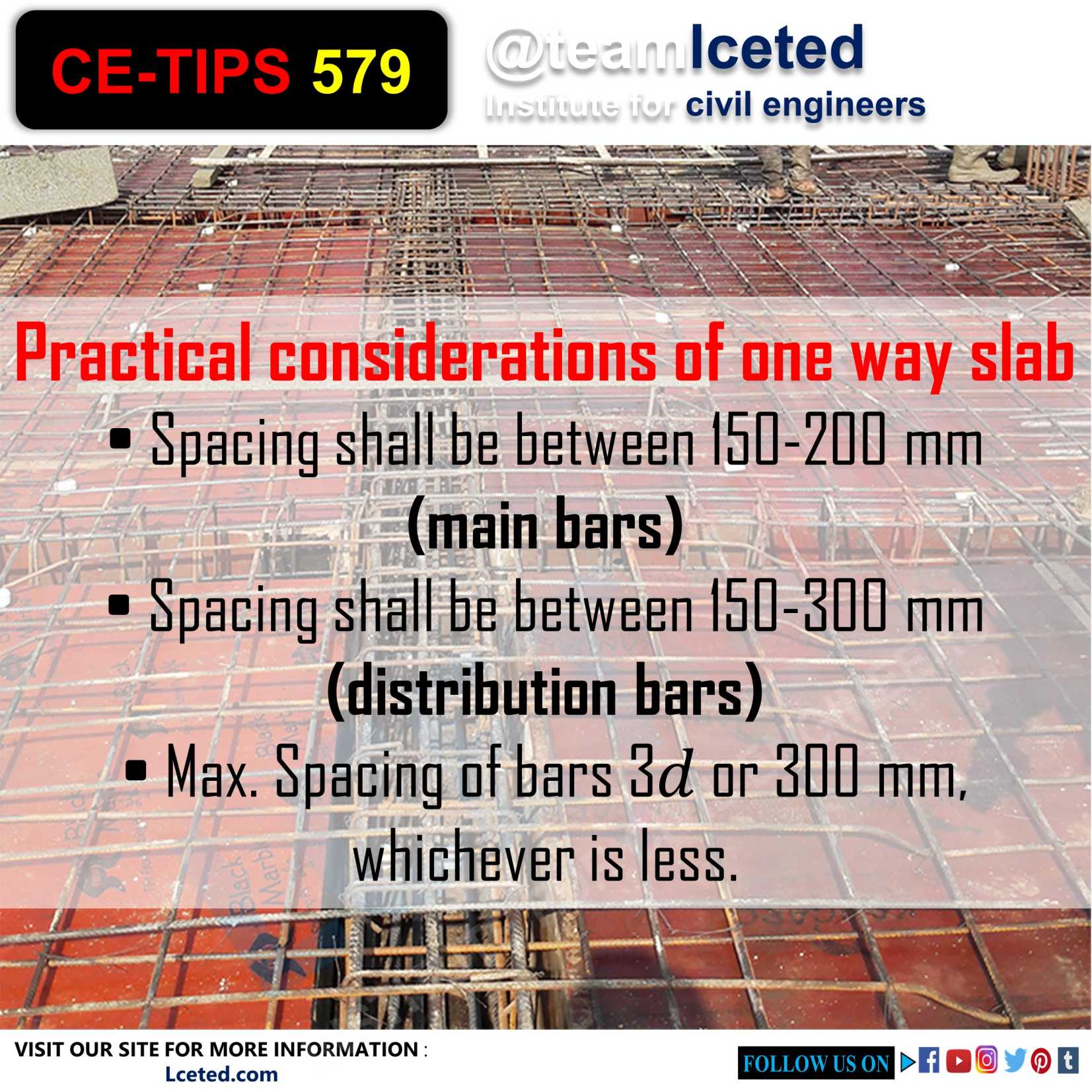

Practical

considerations of one-way slab

• Spacing shall be between 150-200 mm (main bars)

• Spacing shall be between 150-300 mm (distribution

bars)

• Max. Spacing of bars 3𝑑 or 300 mm,

whichever is less.

If you find

This information helpful, please share it.

Thanks! For reading the article.

No comments:

Post a Comment