CURING OF CONCRETE

WHAT IS CURING?

Curing is

the name was given to the procedures used to improve the hydration of cement and

temperature control and the movement of moisture from the concrete. It plays an important role in the strength development

and durability of concrete.

WHY CURING OF CONCRETE IS IMPORTANT?

Curing is done to control

the rate and amount of moisture loss from the concrete to ensure the

uninterrupted hydration of the Portland cement after the concrete has been

placed and finished in its final stage.

"Drying"

concrete does not reach its design strength or meet the specifications. The

longer the Curing treatment, the better the concrete.

REASONS TO CURE CONCRETE

There

are several important reasons why concrete should be cured:

· Increases

Strength Of Concrete

· Increases

The Durability Of Concrete.

· Harder

And More Abrasion Resistant Surfaces

· Improved

Serviceability

· Improved

Microstructure

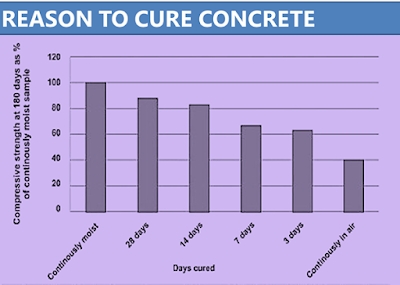

Increases Strength Of Concrete

Strength

of concrete increases - Concrete increases in strength with moisture and has a

favourable temperature for hydration of cement.

“Cement, Concrete & Aggregates

Australia" (CCAA) conducted an experimental inquiry into the importance of curing

Comparing the strength of

concrete in 180 days of moist curing with various periods of moist curing (0,

3, 7, 14 & 28 days) and then allowing it to dry is illustrated in below

picture.

From the diagram below, it

can be seen that the concrete is allowed to dry immediately, reaching only 40%

of the water strength of the same concrete cured for the entire period of 180

days.

Increases The Durability Of Concrete

The life of concrete is

affected by many factors including its permeability, porosity and absorption.

Well-cured concrete reduces

heat, plastic and drying shrinkage cracks, making concrete more watertight,

thus preventing moisture and water-dispersing chemicals from entering the

concrete, thus increasing its durability.

Improved Serviceability

Concrete that is allowed to

dry quickly undergoes considerable shrinkage at an early age. Improper curing

contributes to weak, dusty surfaces having poor abrasion resistance.

Improved Microstructure

Material

properties are directly related to their microstructure. The curing cement

hydration reaction progresses smoothly and forms a calcium silicate hydrate

gel, which binds the aggregates leading to a rock-solid mass, reducing the porosity of the concrete and improving the physical and mechanical properties

of the concrete.

DURATION OF CURING

The curing time of concrete

depends on the Grade and type of cement, the mixing ratio, the desired concrete

strength, the shape and size of the concrete member and the environmental and

exposure conditions. The duration can vary from a few days to a month.

In the case of ordinary Portland cement (OPC), the

exposed concrete surfaces shall be kept continuously wet or wet conditions by

by covering them with sacks hessian

cloth or other similar material or ponding,

and shall be kept continuously moist for at least 7 days at as of the date of

pouring.

Therefore, concrete used with mineral admixtures or

mixed cement, it is recommended to extend the above minimum periods to 10-14

days to facilitate the secondary reaction.

Curing Requires Adequate Moisture, Temperature & Time

If

any of these factors are neglected the desired properties will not develop.

METHODS TO CURE CONCRETE

Methods

of curing concrete are widely included in the following categories:

Water Curing: the

loss of moisture from the concrete surface prevented by constantly wetting the exposed surface of the concrete.

Membrane Curing: Reducing

Moisture Loss from Concrete Surface by covering it with an impermeable

membrane.

Steam Curing: Raising

the temperature of concrete and by keeping surface wet will accelerate

accelerate the rate of strength gain

1. WATER CURING

Ponding: This is the most common and

cost-efficient method of curing flat surfaces such as concrete slab, flat

roofs, pavements, and other horizontal surfaces.

A dike around the edge of

the slab, which may be sub-divided into

smaller dikes is erected and filled with water to create a shallow pond. Care

must be taken to ensure that the pond water does not dry out as it can lead to

an alternate drying and wetting condition.

Wet Coverings: Water-absorbent

cloth such as hessian, burlap, cotton mats, rugs, etc. can be used to cover the

entire surface and maintain water on the concrete surface as soon as the

concrete is set. Due to the capillary action, they must be constantly moist to

prevent water from absorbing from the concrete body.

Sprinkling, fogging & mist curing: The use of a good spray or

mist or water mist is an efficient method of water supplying to the concrete

surface especially during hot weather, which helps to reduce the temperature of

the concrete and ultimately retains moisture inside the concrete body.

2.

IMPERMEABLE MEMBRANE CURING

This process done Occasionally,

concrete work is carried out in areas with severe water shortages.

The amount of water

normally mixed to make concrete is more than enough to hydrate the cement, and

this water is not allowed to leave the concrete body.

The concrete is covered by

a membrane, which effectively clogs the vapour from the concrete.

Formwork Leaving

the formwork at an early age of the concrete is one of the most effective

methods of healing, especially for columns. However, turning the time of the

formwork is significantly reduced.

Plastic Sheeting: Plastic

sheeting forms an effective barrier to control moisture loss from the concrete

surface, provided they are secured in place and protected from damage. They

should be placed immediately after the final set of the concrete without

causing any damage to the surface.

On flat surfaces such as slabs, pavements, etc., they

must be properly secured to the surface and must extend beyond the edges of the

slab, so that they are not blown away by gusts of wind.

Membrane curing compounds:

The curing compounds are

wax, acrylic and water-based liquids, which are sprayed onto the newly finished

concrete, forming a membrane that reduces the loss of moisture content from the

concrete. These are low-cost methods of healing that are difficult to follow

with standard procedures.

When

used to cure concrete, application time is critical for maximum performance.

They should be used when the free water on the surface evaporates and there is

no water sheen on the surface. Very early application dilutes the membrane,

where too late application is absorbed into the concrete. Care should be taken

to avoid foot, machinery and vehicle traffic on the concrete surface to prevent

damage to the finish.

3.

STEAM CURING

Steam curing is a process

of accelerating the initial hardening of concrete and mortar by exposing them

to steam and moisture.

This type of system is

commonly used for precast concrete products that are manufactured in the

factory and have a very fast turning time of formwork.

In the curing chamber, the

control of temperature and humidity is of prime importance or else the concrete

products are likely of fracture, crumble and develop other problems later in

their service lives.

This

type of curing systems are generally adopted for railway sleepers, concrete

blocks, pipes, manhole covers, poles, pipe culverts, prestressed precast

concrete products, and so forth.

CURING IN HOT WEATHER

1. In

hot weather, concrete should be protected from over-drying and direct sunlight

and wind.

2. Curing

materials that reflect sunlight should be used to reduce the temperature of the

concrete.

3. Wet

curing is recommended and care should be taken to avoid excessive stress.

4. Caused

by alternate wetting and drying or by cold water on hot concrete. canvas

tarpaulins or sun shades framed enclosures can be used to protect concrete from

direct sunlight.

CURING IN COLD WEATHER

1. Some

problems associated with a temperature below 4 ° C are:

2. Freezing

of concrete before adequate strength has developed

3. Slow

development of concrete strength

4. Thermal

stresses induced by cooling hot concrete to colder ambient temperatures.

5. In

cold weather, certain procedures such as heated enclosures, insulating blankets

and curing products may be used.

6. The temperature of fresh concrete should be kept above 100 ° C using heated raw materials and hardening should be continued for a longer period until the concrete acquires the desired strength.

CONCLUSION

1. Chemical

reactions between cement and water form the C-S-H gel, which binds to the

concrete material. Coarse and fine aggregates, mineral compounds etc. turn

these pieces into a rock-solid mass.

2. This

is only possible if the treatment is continuous for at least 14 days;

Regardless of the type of cement used.

3. With

a dense microstructure and flawlessness, prolonged curing can lead to improved

longevity.

4. Well-formed

concrete can give poor life if not properly cured, on the other hand moderately

designed concrete will give better life if well treated. So the importance of curing

should never be ignored.

5. At

many sites, concrete curing is left to the end and comfort of the unskilled

worker.

6. Site

engineers and supervisors should make extra effort to ensure that on-site

healing is not neglected and that they provide the resources needed for a

satisfactory level of healing using the best technique available on site.

7. Just

like a newborn baby, when it comes to this world, it needs great care for its

growth and protection from this new environment, similarly, newly placed

concrete needs proper protection and care from the environment and aggressive

environment.

8. Strict

adherence to good curing practices on site will help the concrete achieve the

properties of designed strength, improved durability, improved microstructure

and longer service life.

If you find

This information helpful please share it.

Thanks! For reading the article.

No comments:

Post a Comment