INTRODUCTION

An earthquake by itself is not a disaster, it is a natural phenomenon that results from ground movement, sometimes violent.

These produce surface waves, which cause a vibration of the ground and structures standing on top.

Depending on the characteristics of these vibrations, the ground may develop cracks, fissures and settlements.

The possible risk of loss of life adds a very serious dimension to seismic design, putting a moral responsibility on structural engineers.

In recent times, many new systems have been developed, either to reduce the earthquake forces acting on the structure or to absorb a part of seismic energy.

One of the most widely implemented and accepted seismic protection systems is base isolation.

What Is Base Isolation?

Base isolation is one of the most widely accepted seismic protection systems in earthquake-prone areas.

It mitigates the effect of an earthquake by essentially isolating the structure from potentially dangerous ground motions.

Seismic isolation is a design strategy, which uncouples the structure for the damaging effects of the ground motion.

The term isolation refers to reduced interaction between structure and the ground.

When the seismic isolation system is located under the structure, it is referred to as “base isolation”.

The other purpose of an isolation system is to provide an additional means of energy dissipation, thereby reducing the transmitted acceleration into the superstructure.

The decoupling allows the building to behave more flexibly which improves its response to an earthquake.

The concept of base isolation is explained through an example of a building resting on frictionless rollers.

When the ground shakes, the rollers freely roll, but the building above does not move.

Thus, no force is transferred to the building due to shaking of the ground; simply, the building does not experience an earthquake.

CONCEPT OF BASE ISOLATION

The concept of base isolation is explained through an example of a building resting on frictionless rollers.

When the ground shakes, the rollers freely roll, but the building above does not move.

Thus, no force is transferred to the building due to shaking of the ground; simply, the building does not experience an earthquake.

|

Now, if the same building is rested on flexible pads that offer resistance against lateral movements, then some effect of the ground shaking will be transferred to the building above.

The flexible pads are called base-isolators, whereas the structures protected using these devices are called base-isolated buildings.

The main feature of the base isolation technology is that it introduces flexibility in the structure.

A careful study is required to identify the most suitable type of device for a particular building. Also, base isolation is not suitable for all buildings.

The most suitable structures for base isolation are Low to medium-rise buildings rested on hard soil underneath

High-rise buildings or buildings rested on soft soil are not suitable for base isolation.

PRINCIPLE OF BASE ISOLATION

The fundamental principle of the base, isolation is to modify the response of the building so that the ground can move below the building without transmitting these motions into the building.

A perfectly rigid building will have a zero period.

When the ground moves the acceleration induced in the structure will be equal to the ground acceleration and there will be zero relative displacements between the structure and the ground.

The structure and ground move the same amount.

A perfectly flexible building will have an infinite period.

For this type of structure, when the ground beneath the structure moves there will be zero acceleration induced in the structure and the relative displacement between the structure and the ground will be equal to the ground displacement. So inflexible structures the structure will not move, the ground will.

|

| PRINCIPLE OF BASE ISOLATION |

When Base Isolation System Is Suitable?

Earthquake protection of structures using base isolation technique is generally suitable if the following conditions are fulfilled

1. The subsoil does not produce a predominance of long-period ground motion.

2. The structure is fairly jointed with a sufficiently high column load.

3. The site permits horizontal displacements at the base of the order of 200mm or more.

4. Lateral loads due to wind are less than approximately 10% of the weight of the structure.

Difference Between Fixed And Isolated Base Structure

· When the earthquake is affected on the fixed base structure at that time structure is not defending against the earthquake.

· But in a base-isolated structure, when an earthquake is affected on the structure building is defending against earthquake very well.

· In a fixed structure, the structure moves with ground motion.

· In an isolated structure, the structure does not move with ground motion. But isolation bearing moves with ground motion. So we can say the structure is safe.

Types Of Base Isolators

ISOLATORS | |||

Elastomeric isolators | Sliding Isolators | ||

Natural rubber bearing

| Low damping rubber bearing

| Flat sliding bearing(resilient friction system)

| Spherical sliding bearing(friction pendulum system)

|

Lead rubber bearing

| High damping rubber bearing

| ||

Elastomeric Isolators

▶ Natural Rubber Bearings

▶ Low-Damping Rubber Bearings

▶ Lead-Rubber Bearings

▶ High-Damping Rubber Bearings

Sliding Isolators

▶ Resilient Friction System

▶ Friction Pendulum System

Elastomeric Isolators

These are formed of horizontal layers of natural or synthetic rubber in thin layers bonded between steel plates.

The steel plates prevent the rubber layers from bulging and so the bearing is able to support higher vertical loads with only small deformations.

Plain elastomeric bearings provide flexibility but no significant damping and will move under service loads.

Low damping natural rubber bearing

Damping ratio = 2% to 3%

Manufacturing is easy. Response not strongly sensitive temperature, rate of loading and ageing.

Shear strain is exceeded up to 100%.

High damping natural rubber bearing

Damping is increased by adding extra-fine carbon black, oils or resins and other fillers.

Maximum shear strain = 200 to 350%

Damping ratio = 10 to 20% at 100% shear strain

Effective damping depends on:

· Velocity Of Loads

· Load History

· Temperature

Lead Rubber Bearings

A lead-rubber bearing is formed of a lead plug force-fitted into a pre-formed hole in an elastomeric bearing.

The lead core provides rigidity under service loads and energy dissipation under high lateral loads.

Top and bottom steel plates, thicker than the internal shims, are used to accommodate mounting hardware. The entire bearing is encased in cover rubber to provide environmental protection.

When subjected to low lateral loads (such as minor earthquake, wind or traffic loads) the lead rubber bearing is stiff both laterally and vertically.

The lateral stiffness results from the high elastic stiffness of the lead plug and the vertical rigidity (which remains at all load levels) result from the steel-rubber construction of the bearing.

|

| Lead Rubber Bearings |

Sliding isolators

The second most common type of isolation system uses sliding elements between the foundation and base of the structure.

By high tension springs or laminated rubber bearing by making sliding curved surface.

These mechanisms provide a restoring force to return the structure to its equilibrium position.

A. Flat Sliding Isolators (Resilient Friction System)

Two types of flat sliding isolators:

· With a recentering capacity

· Without recentering capacity

1. Sliding Isolator Without Recentering Capacity

This consists of a horizontal sliding surface, allowing a displacement and thus dissipating energy by means of defined friction between both sliding components and stainless steel.

One particular problem with a sliding structure is the residual displacements that occur after major earthquakes.

2. Sliding Isolator with Recentering Capacity

Compared with sliding isolators, sliding isolation pendula (SIPs) with recentering capacity have a concave sliding plate.

Due to geometry, each horizontal displacement results in a vertical movement of the isolator.

The potential energy, stored by the superstructure, which has been pushed to the top, automatically results in recentering the bearing into a neutral position.

They remain horizontally flexible, dissipate energy and recenter the superstructure into a neutral position.

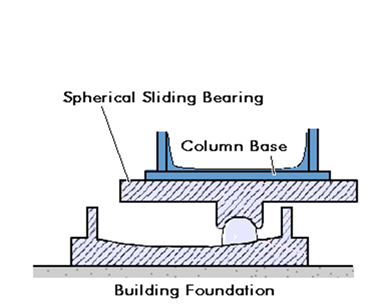

B. Spherical sliding isolators (Rollers) (Friction pendulum)

The friction pendulum system is a sliding isolation system wherein the weight of the structure is supported on spherical sliding surfaces that slide relative to each other when the ground motion exceeds a threshold level.

Isolator Locations

The requirement for the installation of a base isolation system is that the building is able to move horizontally relative to the ground, usually at least 100 mm.

The most common configuration is to install a diaphragm immediately above the isolators.

If the building has a basement then the options are to install the isolators at the top, bottom or mid-height of the basements columns and walls.

What are the Advantages of base isolation?

· Reduced the seismic demand of the structure, thereby reducing the cost of the structure.

· Less displacement during the earthquake.

· Improves safety of the structure.

· Reduced damages caused during the structure.

What are the Disadvantages of base isolation?

· Challenging to implement in an efficient manner.

· Allowance for building displacements.

· Inefficient for high rise buildings

· Not suitable for buildings rested on soft soil.

What are the Applications of base isolation?

· Bridges

· Buildings

· Historic structure

CONCLUSION

The seismic base isolation method has proved to be a reliable method of earthquake-resistant design.

The success of this method is largely attributed to the development of isolation devices and proper planning.

Adaptable isolation systems are required to be effective during a wide range of seismic events.

Efforts are required to find the solutions for the situations like near-fault regions where a wide variety of earthquake motions may occur.

ALSO READ: Design Guide of Earthquake Resistant Masonry building

FAQ

How do base isolators work and what is their purpose?

If you find

This information

helpful, please share it.

Thanks! For reading the article.

No comments:

Post a Comment