PLATE LOAD TEST

This

is one of the most commonly used methods for determining the allowable bearing capacity of soils.

Working

principle

In

this test the loading platform, consisting of a bearing plate of steel or cast

iron or composite material made of wooden sleepers and steel joist is

subjected to a gradual increment of load and the corresponding settlement

values are noted. The load settlement curve is then plotted from which the

ultimate bearing capacity is found as based on settlement considerations for

cohesive and non-cohesive soils. Finally, by dividing this ultimate bearing

capacity by the suitable factor of safety, the allowable bearing capacity of

soil is found out.

Test set-up

The

test pit should be at least five times as wide as the test plate. The test plate

is made to rest in the centre of the pit in a depression that is of the same

size as that of the test plate and the bottom level of which shall correspond

to the level of the actual foundation. The depth of the hole shall be such that

the ratio of depth to the width of the loaded area is the same as for the actual

foundation. The test plate is 2.5 cm in thickness and the following are their

sizes for different soils.

a. Clayey soils, sandy and silty soils

– size, 60 cm square

b. Gravelly and dense sandy soils –

size, 30 cm square

Larger

sizes up to 75 cm square can be used depending upon practical considerations.

The

test plate should be machined on the sides and edges. The sides of the pit are

lined with wooden sheeting if the soil is soft. The test plate shall be bedded

to the soil by plaster of Paris, aluminous cement slurry or fine sand. At the

start of the test, the platform will be preloaded with a load of 0.7 kg/cm2 and

released.

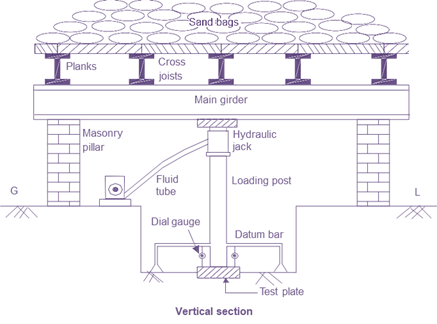

TESTING PROCEDURE AND OBSERVATIONS

The

load is applied through a column by means of deadweights such as sandbags or

pig iron on lead bars or by a reaction frame which may be a truss frame

anchored to the soil by anchors or jacking against a loaded platform with a

steel joist placed centrally underneath. The hydraulic jack should butt against

the joist with

a

ball bearing placed in between. The load is increased in regular increments of

200 kg or one-fifth of the approximate ultimate bearing capacity or until the

ultimate load is reached.

The

settlements should be recorded at least to an accuracy of 0.02 mm with the help

of at least two dial gauges to take care of any differential settlement that may

occur. Settlements should be observed for each increment of load after an

interval of 1, 4, 10, 20, 40, 60 minutes and thereafter at hourly intervals. In

the case of clayey soils, the time-settlement curve should be plotted at each

load stage and the load should be increased to the next stage either when the

curve indicates that the settlement has exceeded 70 –80 per cent of the

expected ultimate settlement at that stage or at the end of a 24-hour period.

For soils other than clayey soils, each load increment shall be kept for not

less than 1 hour and up to the time when no further measurable settlement

occurs. The next increment of load shall then be applied and the observation is

repeated (Figure).

LIMITATIONS OF PLATE LOAD TEST

a. Size effect: The results of the plate load test reflect the strength

and the settlement characteristics of the soil within the pressure bulbs. As

the pressure bulb depends on the size of the loaded area, it is much deeper for

the actual foundation as compared to that of the plate. The plate load test

does not truly represent the actual conditions if the soil is not homogenous

and isotropic to a large depth.

b. Scale effect: The ultimate bearing capacity of saturated clays is

independent of the size of the plate, but for cohesionless soils, it increases

with the size of the plate. To reduce the scale effect it is desirable to repeat

the plate load test with plates of two or three different sizes, extrapolate the

bearing capacity for the actual foundation and take the average of the values

obtained.

c. Time effect: A plate load test is essentially a test of short duration.

For clayey soils, it does not give the ultimate settlement. The load settlement curve is not truly representative.

|

| PLATE LOAD TEST |

d. Interpretation of failure load: A failure load is well defined, except in the case of a

general shear failure. An error of personal interpretation may be involved in

other types of failure.

e. Reaction load: It is not practical to provide a reaction of more than

250 KN and, hence, the test on a plate of size larger than 0.6 m width is

difficult.

f. Water table: The level of water table affects the bearing capacity of

the sandy soils. If the water table is above the level of the footing, it has

to be lowered by pumping before placing the plate. The test should be performed

at the water table level if it is within 1 m below the footing.

If you find

This information helpful, please share it.

Thanks! For reading the article.

No comments:

Post a Comment