COST OF CONSTRUCTION EQUIPMENT

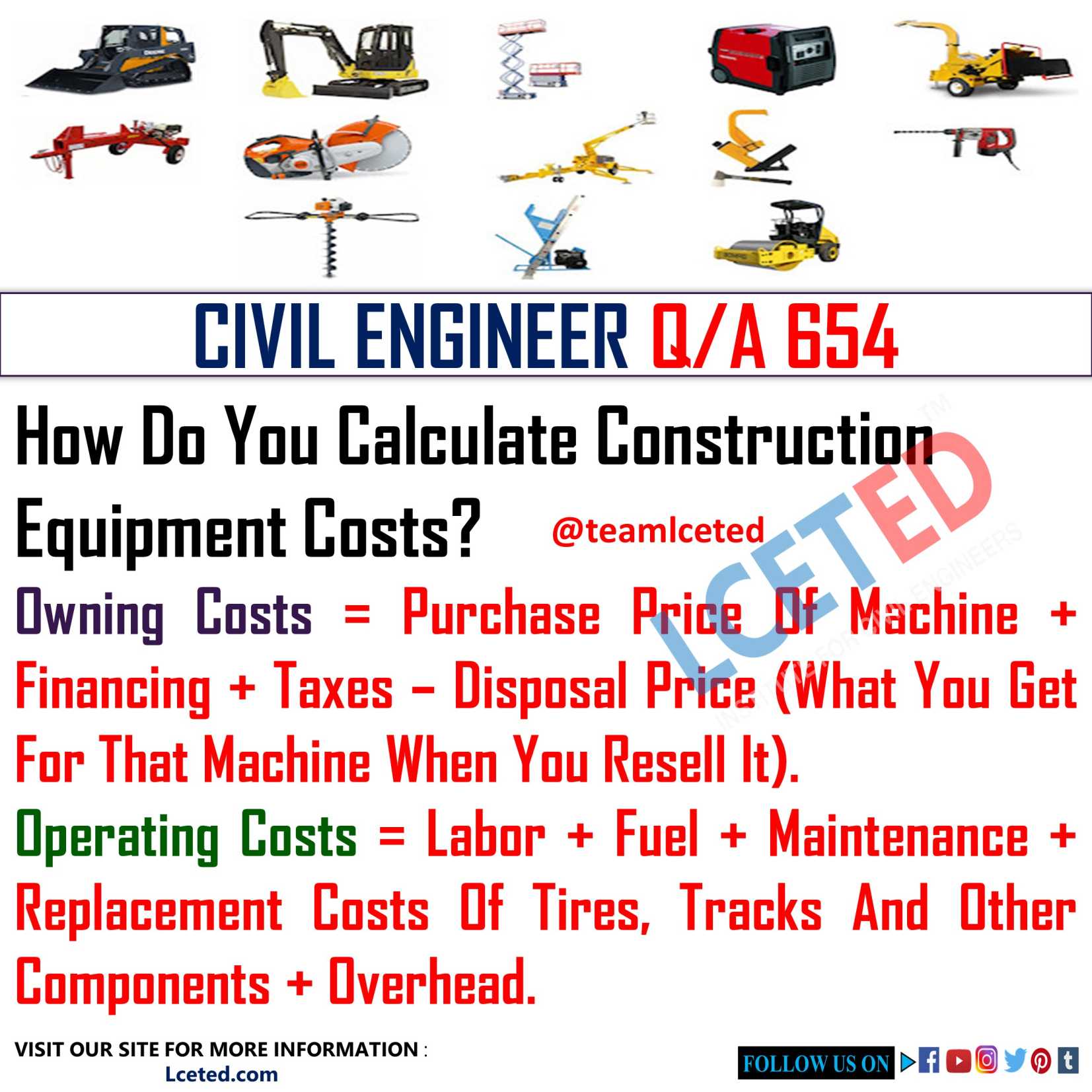

How Do You Calculate Construction Equipment Costs?

PROCUREMENT COST

Procurement cost includes

(I) The Cost Price Of The

Equipment,

(II) Interest On Money

Invested On The Purchase,

(III) Taxes Paid And

(IV) Insurance Cost.

Evidently, the owner of the

equipment pays cash for the procurement of the equipment. It is to be noted

that if the same amount is invested in some other scheme what would be the

turnover. One should get a higher amount annually by investing in the

equipment. Each year the equipment earns for the owner and in the process, its

value gets depreciated. Thus the investment in the equipment is therefore

reduced by the amount of depreciation. A realistic rate of interest would be

the one based on the average value of the equipment during its useful life. The

average value of the equipment has to be determined.

On the depreciated value of

the equipment, the insurance and taxes are paid. The expenses also should be

worked out on the average value of the equipment. These aspects are to be

considered before investing in the procurement of equipment.

OPERATING COST

The operating cost of equipment is based on the following

factors:

(i) Cost of investment

(ii) Depreciation cost

(iii) Cost of major repair

(iv) Cost of fuel and lubricants

(v) Cost of labour

(vi) Servicing and field repairs

(vii) Overheads

1. Cost of Investment

By investment made on the

equipment the owner is losing an amount equal to the interest or return one

would have otherwise been received from banks or other sources of investment. For the

purpose of calculating the total cost of investment, the interest, the taxes,

insurance, etc., may be taken as 10–15% of the cost of equipment.

2. Depreciation Cost

Because of wear and tear, the cost of equipment gets depreciated. An amount of earning has to be set

aside, to balance the depreciation, so that the accumulated amount can be used

at the end. This amount is recovered from the earnings of the equipment and

forms a charge on the operating cost.

3. Cost of Major Repair

Major repairs are those

which are incurred when the equipment is taken to a workshop. This repair

involves the replacement of major parts of the equipment, overhauling and

servicing. This incurred expense is added to the capital cost so that the

expenditure is distributed over the years and included in the operating cost of

the machine.

4. Cost of Fuel and Lubricant

While calculating the fuel

consumption of the equipment, it is the general practice to consider the full

load condition and constant speed under favourable conditions. As the equipment

would not be working always at the ideal condition and so a reduction factor of

60% is considered.

5. Cost of Labour

The cost of labour includes

(i) the wages of the working crew and (ii) the wages of supervisory staff.

6. Servicing and Field Repair

All expenses involved in

the maintenance normally met during the operation of equipment except major

repairs are included under this. This demands periodical service of the

equipment.

7. Overhead

In a large project, the

whole establishment is work charged. Any unforeseen expenses which are not work

charged or non-productive are distributed to the various work producing

elements for purpose of cost control.

SOURCE: BUILDING CONSTRUCTION MATERIALS AND TECHNIQUES | P. PURUSHOTHAMA RAJ

If you find

This information is helpful, please share it.

Thanks! For reading the article...

No comments:

Post a Comment