LABORATORY TESTS ON CEMENT

The following tests are conducted on cement in the

laboratory (IS: 4031 – PT 1 to 15, 1989):

1. Fineness Test

2. Consistency Test

3. Setting Time Test

4. Strength Test

5. Soundness Test

6. Tensile Strength Test

7. Heat of Hydration Test

8. Chemical Composition Test

9. Specific Gravity Test on Cement

Fineness Test

The fineness of cement is responsible for the rate of

hydration and rate of evolution of heat and hence on the rate of gain of

strength. The finer the grains the more is the surface area and the faster the development

of strength.

The fineness of cement can be determined by the

following tests:

1. Sieve Test or

2. Air Permeability Test

1. Sieve

Test

About 100 g of cement is weighed and sieved using a

90-micron IS sieve. Air-set lumps are broken and the cement is sieved

continuously in a circular and vertical motion for a period of 15 minutes. A

mechanical sieve shaker may also be used. The residue left on the sieve is

weighed. This weight shall not exceed 10% for ordinary cement. This test is

rarely used.

2. Air

Permeability Test

The fineness of cement is represented by the specific

surface, which is expressed as the total surface area in sq. cm/g. of cement.

Blaine’s Air Permeability Test is used to find the specific surface.

The principle is based on the relationship between the

rate of flow of air through a cement bed. The cement bed is of a given porosity

comprising the surface area of the particles. The surface area is more for

finer particles.

Consistency Test

Consistency Test is conducted to find the setting times

of cement, viz., initial setting time and final setting time. The test is

conducted using a standard consistency test apparatus, viz., Vicat’s apparatus

(below figure).

Vicat apparatus with various plungers

Standard or normal consistency of cement paste is

defined as that water content which will permit a Vicat plunger of 10 mm

diameter and 50 mm length to penetrate depths of 33–35 mm within 3–5 minutes of

mixing. The test has to be repeated thrice. Each time the cement is mixed with

water varying from 24 to 27% of the weight of cement. It is required that the

test be conducted at a constant temperature of 27 ± 2°C and at a constant

humidity of 20%.

The test procedure is simple. The paste prepared within

3–5 minutes is filled into the Vicat mould and shaken to expel air. The

standard needle is brought down to touch the sur- face of the paste and quickly

released allowing to sink into the paste by its own weight. The depth of the penetration

is noted. Then that percentage of water that allows the plunger to penetrate

only to a depth of 33–35 mm is known as the percentage of water required to

produce a cement paste of standard consistency.

Setting Time Tests

An arbitrary division has been made for the setting time

of cement as the initial setting time and final setting time. Vicat’s apparatus

is used for setting times also.

1. Initial

Setting Time

About 500 g of the cement sample is taken and water

content 0.85 P, where P is the percentage of water required as per the

consistency test is added and made into a paste. The paste has to be made

within a period of 3–5 minutes and filled into the mould.

For this test, a needle of 1 mm square size (needle C)

is used. The needle is allowed to penetrate into the paste. The time taken to

penetrate 33–35 mm depth is taken as the initial setting time.

2. Final

Setting Time

The needle C is replaced by needle F. The attachment is

lowered gently to cover the surface of the test block. The central needle makes

an impression, whereas the circular cutting edge fails to do so. That is, the

paste has attained hardness, and the centre needle does not penetrate the paste

more than 0.5 mm. Thus, the time at which the needle does not penetrate more

than 0.5 mm is considered to be the

final setting time.

Strength Test

The strength of cement can not be determined directly on

cement. Instead, the strength of cement is indirectly determined on

cement-mortar of 1:3, and the compressive strength of this mortar is the

strength of cement at a specific period.

For this test, 555 g of standard sand and 185 g of

cement is mixed with water quantity P/4 + 3% of the combined weight of the

cement and sand mixture. These are mixed thoroughly within 3–4 minutes. The

mixed paste is filled in a cube mould of size 7.06 mm, which has a face area of

50 sq cm. The mortar is compacted by a tamping rod or in a vibrator. The moulds

have to be kept in a room with a controlled temperature of 27 ± 2°C and at

least 90% humidity. If this facility is not available, the moulds are kept

under a wet gunny bag to simulate 90% relative humidity. The cubes are removed

from the mould after 24 hours and kept immersed in clean water till taken out

for testing.

Three cubes are tested for compressive strength after a

specific period (viz., 3, 7 or 28 days). The period is being reckoned with from the

completion of vibration. The average compressive strength of the three cubes

gives the strength of cement at the specific period.

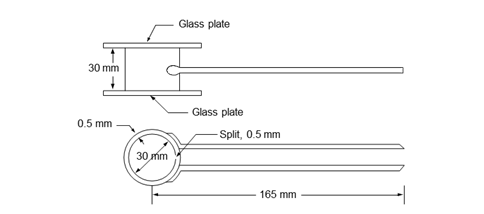

Soundness Test

The Soundness Test is performed to detect the presence

of uncombined lime and magnesia in cement. This test is conducted in Le Chatelier’s

apparatus (below figure). It consists of a small brass cylinder of 30 mm

diameter, 30 mm height and 0.5 mm thickness, which is split along its

generation with the split not exceeding 0.5 mm. On either side of the split,

two indicators with pointed ends are provided.

Le Chatelier’s apparatus

The cement paste is

prepared with water content at consistency. The cylinder is placed over a glass

plate and is filled with cement paste. It is covered with another glass

plate on the top. The whole assembly is immersed in water at 24–35°C for 24

hours. After 24 hours, the gap between the indicators is measured.

The mould with the specimen

is immersed in the water again and boiled for 30 minutes. After boiling for 1 hour,

the mould is taken out and cooled. Again the gap between the indicators is

measured after the end of cooling. The increase in the gap represents the expansion

of cement.

Tensile Strength Test

This test is conducted using a cement-mortar briquette

in a tensile testing machine. The dimensions of the briquette are shown below

figure.

Standard cement-mortar briquette

A 1:3 cement–sand mortar with a water content of 8% is

mixed and moulded into a briquette in the mould. It is cured for 24 hours at a

temperature of 27 ± 2°C and for 24 hours in an atmosphere at 90% relative

humidity.

The briquette is tested under direct tension, the pull

being applied through special jaws engaging the wide ends of the briquette. The

area of the cross-section at the neck is 1 sq inch (i.e., 25.4 mm × 25.4 mm). The

average strength for six briquettes tested after 3 and 7 days is recorded.

The heat of Hydration Test

During the hydration of cement, heat is produced due to

chemical reactions. In a large-scale construction, this heat may raise the

temperature of concrete to a high degree to as high as 50°C. In such cases, low-heat cement has to be used or cooling methods must be employed.

The test is conducted using a calorimeter adopting the

principle of determining heat gain. Low-heat cement should not generate 65

calories per gram of cement in 7 days and 75 calories per gram of cement in 28

days.

Chemical Composition Test

Different tests are conducted to determine the quantity

of various constituents of cement. The requirements as stipulated in IS:

269–1998 are as follows:

|

1. Ratio of the percentage of alumina to that of

iron oxide |

²

0.66 |

|

2. Lime Saturation Factor (LSF), i.e., ratio

of percentage to that of alumina, iron oxide and silica |

²

0.66 and ³ 1.02 |

|

3. Total loss on ignition |

4% |

|

4. Total sulphur content |

2.75% |

|

5. Weight of insoluble residue |

1.50% |

|

6. Weight of magnesia |

5% |

If you find

This information is helpful, please share it.

Thanks! For reading the article.

Thank you

ReplyDeleteGeart Content

ReplyDeleteIn sub-atomic science where a great deal of synthetic and cell tests are required, pipettes become basic in the exploration.

ReplyDeletepipette calibration

"Highly recommend this team." epoxy flooring Hobart

ReplyDelete