Primarily it is needed to

take preventive measures wherever feasible before facing any failure on a small

or large scale. A small investment or preventive measure is taken at the initial

stage not only prevents failure but also gives a long life of the building.

Then maintenance plays a

major role to make every component of a building function properly and at

the same time increases the lifespan of the building.

Maintenance of floors,

doors and windows, sanitary appliances, water supply, drainage system and electrical

system are all important.

Further, checking of

leakages, identifying the causes of cracks and repairing them or make some

preventive measures to avoid such fractures in future. Special repairs, if any,

are to be attended to then and there. Apart from the routine maintenance annual

general maintenance of a building should be made and implemented.

MAINTENANCE OF

FLOORINGS

As there are many types of floors constructed,

maintenance of some of the important floors are dealt with below.

Terrazzo Floors

Cleaning of terrazzo floors with water may be taken up

after 3 months of laying. After this period, it should be swabbed daily using

clean water and a clean rough swab (floor cloth) which should be rinsed in

water frequently so as to avoid dirt being back onto the floor. The floor is

then allowed to dry in the air. After this initial cleaning, ordinary swabbing

shall keep the floor shining.

Sometimes acid polishing of terrazzo floors is resorted

to after machine polishing during the first laying of the floor. If need be,

this can be repeated. Oxalic acid is used for acid cleaning. After acid

polishing, the following day the floor is wiped with a moist rag and washed

clean with water.

Marble Floors

For marble floors, daily maintenance is to be made. This

is carried out by mopping with a mild detergent in water. Marble gets easily

stained and scarred. If there is a spill on the floor, it should be cleaned

immediately.

Stubborn stains should be removed based on the type. If

the stain is from grease, a paste of chalk dust or whiting with acetone. This

mixture is applied on the stain and allowed to stand overnight. The mixture is

sponged off and the treated area is buffed. If the stain is from any organic

source like tea, fruit juice, etc., chalk powder with hydrogen peroxide mixture

is used. This paste can also remove stains due to rust. Such stains can also be

removed by dry borax and damp cloth followed by warm water rinsing.

Linoleum Floors

For this floor mopping with kerosene oil can pick up all

the dirt. After the removal of dirt, the floor may be wiped with water and

mopped well to set a polished surface.

Concrete Floors

A properly constructed

concrete floor should be dust-free under normal use. Dusts in floors can be

reduced by the application of a hardener, or by waxing, or by painting it with

a solution of oil spirit. For such application, raw or boiled linseed oil

mixed with an equal amount of turpentine has been found to be effective.

Painting with epoxy, acrylic or chlorinated rubber base is also used.

Wax polishing with

proprietary polish is also popularly used. This polish may be made at site by

mixing a 25% solution of melted beeswax in turpentine together with pigment at

the rate of 60% by weight of beeswax. The wax is applied on the floor which

hardens after 12 hours and the surface is sprinkled with French chalk and

polished with dry cloth. About 200 gm of beeswax shall cover an area of 10 m2.

If the floor has to be

roughened, it is usually done by washing the floor with dilute hydrochloric

acid. The dilute acid is applied at the rate of 0.3 l/m2 of floor

area. The acid is left for 15 minutes and then brushed. Then the floor is

thoroughly cleaned with water. If need be three successive applications may be

given.

Other Floors

All stone floors may be

maintained by mopping with mild detergent and water at regular intervals.

Ceramic tile floors are

easy to maintain. Soap and water can be used to clean the floors and special

care has to be taken to clean the joints. Stains, if any, may be removed as

explained in marble floors.

Wooden floor is to be

cleaned and kept bright by polishing with beeswax or ready-made wax polish.

MAINTENANCE OF DOORS

AND WINDOWS

In the maintenance of doors and windows both wood work

and glass, work should be taken care of.

Maintenance of Woodwork

Woods in general get

deteriorated with time due to water and direct exposure to sun. However, teak

wood may need less maintenance. Other woods should be periodically painted and

kept clean. In moist conditions, both dry and wet rots grow which will be the worst

in the toilet room. This can be prevented by providing adequate ventilation and

painting.

The bottom of bathroom doors

has to be protected by painting with waterproof paints. White putty glazing is

used for ordinary wood and in teakwood glazing with beads is usually carried

out.

Maintenance of Glass

Glasses fitted to doors and

windows are kept clean using clean tepid water. In order to remove dirt and

stains cleaning liquids available in the market may be used. Instead, cleaning can

be made by mixing two tablespoons of household ammonia or white vinegar with

1.25 l of water. This is

sprayed using a sprayer. Cleaning has to be taken up from top to bottom and the

glass is dried by a cotton swab followed by a crumbled newspaper. One side has

to be wiped horizontally and the other side vertically.

MAINTENANCE OF WATER

SUPPLY SYSTEM

Sumps and overhead tanks

are to be in closed conditions and should be cleaned periodically. Exposure

of sump and overhead tanks lead to mosquito breeding and the formation of algae.

Taps and other fixtures

should be kept in working condition so as to avoid wastage of water. They

should be repaired wherever they become defective. Taps, chrome fittings,

basins, etc., can be cleaned with liquid ammonia in water. Material for

polishing of metals is also available in the market.

MAINTENANCE OF SANITARY APPLIANCES

The main problems with sanitary applications like water

closets, washbasins, etc., are the growth of fungus and algae. A solution of

chloride of lime (bleaching powder) in hot water will remove surface stains

from ceramic ware and tiles. A simple application of moistened cloth in hot water

and a little paraffin will effectively restore the lustre of porcelain and

glazed surfaces. There are ready-made cleaning materials which are also

available in the market. If the sewage is to be treated by a septic tank, chemicals

and detergents should not be used as they may kill the bacteria in the septic

tank.

MAINTENANCE OF

DRAINAGE SYSTEM

All the soil and waste-disposal system must be kept

clean and should be in working condition. Otherwise, nuisance and unhealthy

conditions prevail. Main items of the drainage system to be taken care of are

discussed below (Varghese, 2012).

Fittings Inside the Buildings

Water taps, wastewater pipes, traps in fittings, grating

above floor trap, etc., should be periodically checked. This is done by pouring

water on them and examining their performance. Otherwise, they are liable to

be clogged if the passage of water is not with adequate force. Gratings at bathrooms

have to be periodically checked for clogging due to hair, oil, etc. Blocking if

any may be removed using drain cleaning compounds or manually wherever

feasible.

Waste and Soil Pipes

Waste pipes and soil pipes which are fixed on the walls

are to be checked periodically. Wherever feasible PVC pipes may be used with

balloons on the top should be checked and replaced if necessary.

Gulley and Manholes

Before the onset of monsoon, gulleys, manholes, manhole

covers and drain pipes are to be examined. In order to prevent backflow from the street sewer, the outlet to the sewer should be checked. By chemical sprays,

cockroaches are to be destroyed and stagnation of water should be avoided.

Roof Drainage System

Before the rainy season, the roof drainage system should

be inspected. Horizontal and vertical drainage systems are to be cleaned and

leakages repaired. Rectification should be attended to, particularly horizontal

drain pipes, to prevent the blockage of wastewater.

Septic Tanks

Grease, slow decomposing matter, etc., should be avoided

in the drains for the efficient working of a septic tank. Further

drain-cleaning chemicals should be avoided which can kill the bacteria in the

septic tank.

When the depth of the sludge and scum exceeds half the

depth of the tank, digested sludge should be removed. A portion of the sludge

should be left in the tank to act as a seed to the fresh sewage. If the action

in the septic tank is dull ¼ kg of brewer’s yeast is added to the tank to hasten

the action. Signs of a defective system is to be noticed when foul colours

appear from the drains or the tank and growth of lush vegetation over the tank.

If water backs up in the drain, it is to be realised that clogging by sludge

and scum has happened.

MAINTENANCE OF

PAINTWORK

Washable paints can be cleaned with clean water. Most of

the paints, viz., soda, soft soap and other alkaline substances are injurious.

In order to remove stains, they should be highly diluted and removed off the

paint with clean water as soon as the dirt is removed.

Re-paint of surfaces have to be done before the old

paint disintegrates. Quality of paint contributes to the life of the work.

Frequent painting of external surfaces may be prevented by the use of special

exterior paints. Also, special paints may be used to paint the underside of the

wet area, such as bathrooms and lavatories if wall tiles are not provided.

All steelworks are to be carefully observed. They

should be regularly cleaned with clean water. Rusted parts, if any, should be

removed and re-painted. Special attention are required if steel windows are

used in buildings.

MAINTENANCE OF

BRICKWORK

Cracks are frequently found in brick masonry walls.

Causes for such cracks have been discussed in the previous post. It has been

discussed that prevention of cracks in brick masonry may be avoided by proper

foundation design and providing different joints such as expansion joints,

isolation joints, sliding joints, etc.

Maintenance of brickwork involves in cleaning, removal

of efflorescence, repairing of cracks, re-painting brickwork and re-painting

old brick joints.

Cleaning Brickwork

Brickwork has to be cleaned with steam or steam and hot

water jets. This treatment is suitable for fine-textured and hard-burnt

bricks. Sandblasting can also be done. However, this disturbs the texture of

the bricks and absorbs the painting.

Removal of Efflorescence in Brickwork

Soluble salts after drying get deposited on the surface

of the walls as a white layer. These salts may be present in the material of the

walls and come out. Sources of these salts are mortars and plasters. As

moisture is the cause for the creation of efflorescence, this can be checked by

proper damp prevention.

Efflorescence can be removed by scrubbing those portions

on the wall with water and a tough brush. For effective use instead of water,

10% of the solution of muriatic acid may be used. After this treatment, the wall

has to be rinsed with clean water or with a weak ammonia solution.

Repairing of Cracks in Brickwork

Cracks in brickwork are rectified by adopting the following

procedure:

1. If the cracks are less than 1.5 mm in width, the

cracks may be filled with commercially available putty.

2. Wider cracks are repaired by releasing them out to

about 25 mm and re-filling with 1 cement, 2 lime, 9 sand mortar or any crack-filling

material available in the market.

3. Still wider cracks may have to be stitched by using

reinforced mortar or concrete stitching blocks.

Re-pointing Old Brickwork

In the case of brickwork which is pointed may be needed

to re-point in order to improve the appearance and to make it watertight.

Generally, mortar at the pointed portions gets lost due to rain, wind, freezing,

etc. The following procedure may be followed for re-pointing:

1. The joint of the old mortar is loosened and scraped

out and cleaned for a depth of at least 3 mm and wetted with water.

2. New mortar is applied to the joints with a special

trowel and pointed as per practice.

Re-painting Brickwork

Re-painting is necessary for walls that have been

previously painted. The type of paint and colour should be decided and

accordingly, the surface has to be prepared.

MAINTENANCE OF

STONEWORK

Maintenance of stonework involves in removing

efflorescence and stains, repair of cracks and waterproofing.

Removal of Efflorescence in Stonework

The appearance of efflorescence occurs commonly due to use

of the certain type of mortars. Removal of efflorescence has to be done as done in

brickwork. Stones are to be kept saturated with water to remove the action of

acids.

Removal of Stains in Stonework

Removal of stains can be done easily if its origin is

known. Iron stains show a rusty appearance which can be removed by rinsing the

area with a solution of ½ kg oxalic acid in 5 l of water. After 2–3 hours, the

surface should then be scrubbed with a brush and clean water. Darker stains may

be removed with six parts of water, one part of sodium citrate and one part of

glycerine, made into a paste with adequate whiting. This paste is applied on

the surface and then kept for a few days.

For very deep and dark stains, one part of sodium

citrate is mixed with six parts of water. This solution is applied to the

surface of stains. This is followed by covering the surface with a thin layer

of sodium hydro-sulphite crystals and removed after an hour. This may be

repeated if needed.

Repair of Cracks in Stonework

Repairing of cracks has to be attended to by ensuring that

the settlement causing the crack has ceased. This generally takes about one

year for the complete settlement.

Small cracks are cleaned with a wire brush and a thick

paste of cement mix is forced into the crack. In order to get a firm key for

the mortar, large cracks should be raked. An inverted V groove is made with a

minimum of 1 cm depth. A cement mortar of 1:2 ratio is applied with less

water. The mixture is forced into the crack to get a firm bond. Along with this

mixture expansive agents are added to improve the bond.

Waterproofing of Stonework

In order to keep the stone

masonry free from dampness, efflorescence, frost action, etc., colour-less

waterproofing materials is applied waterproofing materials obtained from heavy

petroleum distillates, oils or insoluble soaps are best. It is difficult to

waterproof very closely textured stones. Waterproofing materials substances

containing resins are not suitable for fine-textured stonework. Waterproofing

causes some dislocation which goes from the stones in course of time.

CRACKS AND REMEDIAL

MEASURES IN CONCRETE

Causes of cracks, remedial measures and repair of cracks

in concrete are discussed.

Causes of Cracks in Concrete

Cracks in concrete may be plastic shrinkage cracks,

settlement cracks, cracks due to bleeding, cracks due to delayed concrete

casting and cracks due to construction effects are discussed the previous post.

Preventive Measures for Crack in Concrete

Preventive measures for cracks in concrete are discussed

in Section 8.11. Apart from them, joints in concrete structures are provided to

continue a specific work or prevent cracks due to change in temperature.

The following two types of joints are usually provided

in concrete structures:

(i) Construction joints

(ii) Expansion and contraction joints

1. Construction Joints

This type of joints is

provided at the location where the construction is stopped at the end of the day’s

work or for any other reason so as to bridge the old work and the new work by a

proper bond. Such a situation generally occurs when large concrete work has to

be executed which cannot be done within a day.

If the work is well planned

such that the day’s work is to be stopped at an expansion or contraction joint,

in such a case there is no need for a construction joints.

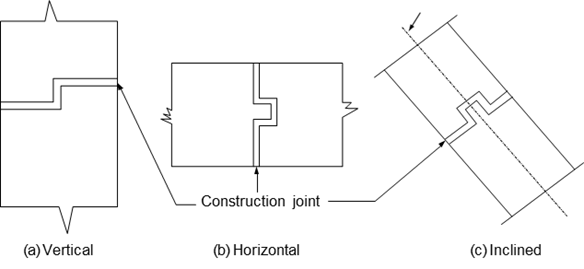

The construction joints may

be vertical, horizontal or inclined depending on the type of structure. In the

case of inclined or curved members, the joint should be perpendicular to the

axis of the structural member. The position of the construction should be well

planned and constructed keeping in view the stability of the structure.

Construction joints may be provided for structures that are vertical,

horizontal or inclined (Fig. below).

Construction

joint in different positions

Depending on the type of concrete structures the

following factors should be considered.

(i)

Columns

Columns should be concreted to a few centimetres below

its junction with the lowest soffit of the beam. Construction above joint

should be at least 4 hours after the completion of the joint. Care should be

taken such that the construction joint is at the location of least bending

moment.

(ii)

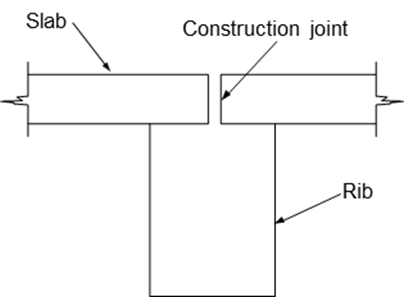

T or L Beams

The ribs of T or L beams are first concreted and then

slabs forming the flanges are concreted up to the centre of the rib

(Fig. below). In certain situations, if a construction joint has to be provided

between the slab and beam, the rib of the beam is concreted up to 25 mm below

the level of the soffit of the slab and the joint should be located at that level.

Construction joint on T-beam

(iii)

Simply Supported Slabs

In slabs supported on two sides, the construction joint

should be vertical and parallel to the main reinforcement. Alternatively the

joint may be provided at the middle of the span perpendicular to the main

reinforcement. For two-way slabs, the construction joint is provided near the

middle of either span.

(iv)

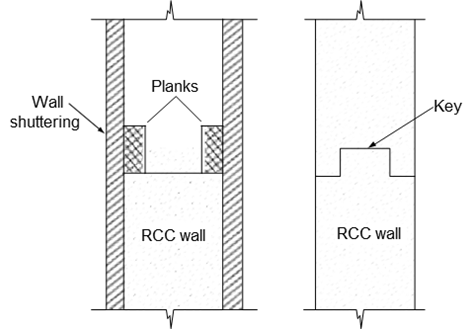

RCC Wall

In this case, the location of the joint depends on the

convenience in placing the framework and the access of compaction of concrete.

The continuity of the joint is made by the formation of a key (Fig. below (a)).

The arrangement of the formation of key and the finished position of the key is

shown in Fig. below (b).

Construction joint

in RCC Walls

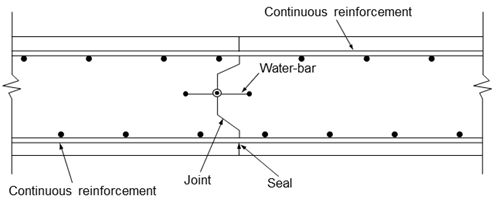

2. Expansion and Contraction Joints

These joints are provided in all concrete structures when the length exceeds 12 m. These joints are made to satisfy the following requirements:

(i) To accommodate for

changes in the volume of concrete due to temperature.

(ii) To retain the

appearance by maintaining the same shape of the concrete structures.

The

joints are filled with some elastic materials like filters or dowels of keys.

The quality of the filter should be in a position to withstand cold weather.

It should be compressible, cellular and not brittle. The Conventional materials

used as filters are strips of metal, bitumen-treated felt, cane fibre-board,

cork, softwood, etc.

The provision of dowels or keys is to transfer the load. The movement due to shrinkage is

controlled by the contraction joint. The contraction joint may be complete or

partial. In the complete contraction joint, there is complete discontinuity of

both concrete and steel (Fig. below). In the partial contraction joint, there is

a discontinuity of concrete but the reinforcement bars are continued across the

joint (Fig. below).

Complete contraction joint

Partial contraction joint

Stitching of Cracks in Concrete Members

At times cracks do develop in concrete members due to

several reasons such as the design of construction deficiency, problems with

concrete, disturbance at an early stage, etc. If such cracks are localized in

nature they can be repaired either by epoxy grouting or by stitching. The

choice of either of them depends on the discretion of the concerned engineer

and the intensity of the cracking (Gambhir, 2010).

Stitching consists of drilling holes on both sides of the

crack, and inserting U-shape metallic strips (stitching dogs) spanning across

the cracks. The bonding of the metallic strips with parent concrete can either

by with non-shrink grout or an epoxy-based bonding system. It is preferable if the

metallic strips are variable in length and orientation with closer spacing at

the ends of cracks (Fig. below).

Stitching of concrete cracks

However, the stitching does not close a crack, but only

prevents it from further widening. Such stitches, when encased with an overlay

have been reported to be performing well in several cases.

Repair of Concrete

by Gunite and Shotcrete

Gunite is one of the popular methods undertaken to

repair cracks and other damages in concrete members. Guniting is the process of

injecting mortar with a low water-cement ratio at high pressure through a

nozzle. This method has been improvised in that only concrete with

small-sized coarse aggregate instead of mortar is used. This method is called

shotcrete.

In both methods, the affected concrete part should

be cleaned before the operation and gunite or shotcrete is applied. Former

small thickness or width of gap gunite is used whereas shotcrete is

recommended for larger thickness. The materials used for gunite are cement,

sand and water and for shotcrete are cement, sand and small aggregate and

water. For the quick setting of gunite, accelerators are also added.

CHECKING BUILDING

LEAKAGE

Although adequate care has been taken by providing

weatherproofing of roofs, leakage may occur with time due to a lack of proper

maintenance. Leakage of the roof due to rainwater may spoil the materials stored

in the room, may damage the electrical circuits, may wet the walls, etc.

Leakages may occur in different types and different parts of a roof which are

discussed below.

Leakage in Sloping Roofs

All parts of the sloping roof are to be checked for leakage.

It is difficult to repair after construction, particularly tiled roofs. It is

generally recommended to apply a waterproofing coating at the construction

stage itself. Tiled roofs leak during heavy rain due to lack of this

precaution.

Other sloping roofs like folded plates, shells, etc.,

are made out of concrete. These roofs would not have been compacted properly

due to the sloping surface. During normal rains, there is no problem with leakage.

During heavy rains, water may seep through the concrete and tend to leak. A

cement coating may fill the porous concrete followed by a waterproofing coating that may stop further leakage.

Leakage of Flat Roofs

Following preventive measures and repairs may be

undertaken to prevent leakage.

1. During the construction stage itself, flat concrete roofs

are to be cured perfectly. Any leakage noticed at this stage can be rectified

easily. All surfaces can be given a coat of hot blown asphalt after curing.

2. Adequate slope may be given to the drainpipe joints

such that stagnation of water is prevented.

3. Wherever the horizontal surfaces meet the vertical or

inclined faces, fillets are to be provided. The gap formed with time has to be

closed periodically.

4. All the entry points of the rainwater should be

checked and should not be blocked by leaves, wastes, etc.

5. Weathering courses, like flat tiles, laid on the roof

should not crack. If cracks are found they should be closed immediate by

grouting or otherwise.

6. Very porous concrete slabs may have to be grouted.

Leakage Through Junction of Walls and Sunshades

This is very commonplace where the leakage occurs which

are to be checked and rectified as discussed below.

1. At the construction stage itself, proper slope and

drainage arrangements are to be checked. Any architectural features made over

sunshade should not give room for the stagnation of water. A throating at the

bottom end of sunshades shall make the water drip properly.

2. In long sunshades there is a possibility of cracking

at the ends. Such cracks make room to flow water on the walls. These cracks

should be filled with bituminous or elastomeric compounds. The top of the sunshade

should be kept clean always, particularly before the onset of the monsoon.

Leakage Through Wall Cracks

All the external cracks found on walls should be

deepened to 5 mm and filled with paintable sealant. In order to keep the

external walls crack-free, waterproof cement or external paint may be used.

Walls containing air-conditioning or other electrical connections may be

painted with silicon paint to prevent the wetting of walls during rains.

MAINTENANCE OF

ELECTRICAL SYSTEM

It is better to have an ELCB trip switch in the

electrical system of the buildings. This is helpful to show the earth leakage.

All electrical switches should be kept clean, particularly ones at the kitchen

which are liable to be clogged up by grits accumulated. In order to avoid the menace of ants and white ants, it is better to keep anti-ant chemicals in the

switch boxes. If the performance of bearings, condensers, regulators, etc., is

not good, they have to be attended to. High amperage gadgets like heaters,

air-conditioners, etc., are liable to get heated up and burnt. They should be

plugged tightly or should be connected through fused outlets. It is advisable

to have phase-changing devices in the electric supply system and thereby

changing phases wherever there is a need. Savings in electricity can be made by

the use of fluorescent lamps, LCD lamps for lighting and capacitance type fans.

This information is helpful, please share it.

Thanks! For reading the article...

SOURCE: Basic Civil Engineering

Fourth Edition

MS. Palanichamy

Vice-Chairman

Tamil Nadu State Council for Technical Education Chennai, Tamil Nadu

No comments:

Post a Comment