The list of potential causes of concrete failures is a long one. A few examples include chemical reactions, shrinkage, weathering, and erosion. Many other potential causes exist, and we will explore them individually. Understanding the causes of concrete structure damage is an important element in the business of rehab and repair work.

UNINTENTIONAL LOADS

Unintentional loads are not

common, which is why they are accidental. When an earthquake occurs and

affects concrete structures, that action is considered to be an accidental

loading. This type of damage is generally short in duration and few and far

between in occurrences.

The visual inspection will

likely find spalling or cracking when accidental loadings occur. How is this

type of damage stopped? Generally speaking, the damage cannot be prevented,

because the causes are unexpected and difficult to anticipate. For example, an

engineer is not expecting a ship to hit a piling for a bridge, but it happens.

The only defence is to build with as much caution and anticipation as possible.

CHEMICAL REACTIONS

Concrete damage can occur

when chemical reactions are present. It is surprising how little it takes for a

chemical attack on concrete to do serious structural damage. The following

sections include examples of chemical reactions and how they affect concrete.

ACIDIC REACTIONS

Most people know that acid

can have serious reactions with a number of materials, and concrete is no

exception. When acid attacks concrete, it concentrates on its products of

hydration. For example, calcium silicate hydrate can be adversely affected by

exposure to acid. Sulfuric acid works to weaken the concrete and if it is able to

reach the steel reinforcing members, the steel can be compromised. All of this

contributes to a failing concrete structure.

Visual inspections may

reveal a loss of cement paste and aggregate from the matrix. Crack- ing,

spalling, and discolouration can be expected when acid deteriorates steel

reinforcements, and laboratory analysis may be needed to identify the type of

chemical causing the damage.

Code Consideration

It is a code violation to embed aluminium conduits and

pipes in concrete unless the aluminium is coated or covered to prevent

aluminium–concrete reaction or electrolytic action between aluminium and steel.

How can you create a more

defensive concrete where chemical reactions are anticipated? Portland cement

concrete does not fare well when exposed to acid. When faced with this type of

concrete, an approved coating or treatment is about the best that you can do.

Using dense concrete with a low water-cement ratio can provide acceptable

protection against mild acid exposure.

Aggressive

Water

Aggressive water is water

with a low concentration of dissolved minerals. Soft water is considered

aggressive water and it will leach calcium from cement paste or aggregates.

This is not common in the United States. When this type of attack occurs,

however, it is a slow process. The danger is greater in flowing waters because

a fresh supply of aggressive water continually comes into contact with the

concrete.

If you conduct a visual

inspection and find rough concrete where the paste has been leached away, it

could be an aggressive-water defect. Water can be tested to determine if water

quality is such that it may be responsible for the damage. When testing indicates

that water may create problems prior to construction, a

non-Portland-cement-based coating can be applied to the exposed concrete

structures.

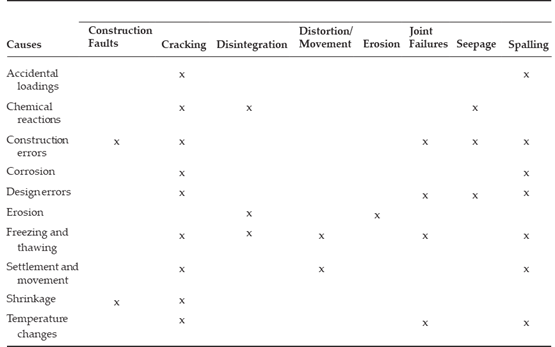

There are many factors that can contribute to problems

with a concrete installation. The table below outlines examples of such problems.

1. Accidental

loadings

2. Chemical

reactions

· Acid

attack

· Aggressive-water

attack

· Alkali-carbonate

rock reaction

· Alkali-silica

reaction

· Miscellaneous

chemical attack

· Sulfate

attack

4. Construction

errors

5. Corrosion

of embedded metals

6. Design

errors

· Inadequate

structural design

· Poor

design details

7. Erosion

· Abrasion

· Cavitation

8. Freezing

and thawing

9. Settlement

and movement

10. Shrinkage

· Plastic

· Drying

11. Temperature

changes

· Internally

generated

· Externally

generated

· Fire

12. Weathering

Alkali-Carbonate Rock Reaction

Alkali-carbonate rock

reaction can result in damage to concrete, but it can also be beneficial. Our

focus is on the destructive side of this action, which occurs when impure

dolomitic aggregates exist. When this type of damage occurs, there is usually

map or pattern cracking and the concrete can appear to be swelling.

Alkali-carbonate rock

reaction differs from alkali-silica reaction because there is a lack of silica

gel exudations at cracks. A petrographic examination can be used to confirm the

presence of an alkali-carbonate rock reaction. To prevent this type of problem,

contractors should avoid using aggregates that are or are suspected to be,

reactive.

Code Consideration

Conduits embedded in concrete must be spaced a minimum

distance that equals not less than three times the diameter of the conduit

being installed.

Alkali-Silica Reaction

An alkali-silica reaction can occur when aggregates

containing silica that is soluble in highly alkaline solutions may react to

form a solid, nonexpansive, calcium-alkali-silica complex or an alkali-silica

complex that can absorb considerable amounts of water and expand. This can be

disruptive to concrete.

Concrete that shows map or pattern cracking and a

general appearance of swelling could be a result of an alkali-silica reaction.

This can be avoided by using concrete that contains less than 0.60% alkali.

Various Chemical Attacks

Concrete is fairly

resistant to chemical attacks. For a substantial chemical attack to have

degrading effects of a measurable nature, a high concentration of the chemical is

required. Solid dry chemicals are rarely a risk to concrete. Chemicals that are

circulated in contact with concrete do the most damage.

When concrete is subjected

to aggressive solutions under positive differential pressure, the concrete is

particularly vulnerable. The pressure can force aggressive solutions into the

matrix. Any concentration of salt can create problems for concrete structures.

Temperature plays a role in concrete destruction with some chemical attacks.

Dense concrete that has a low water-cement ratio provides the greatest

resistance. The application of an approved coating is another potential option

for avoiding various chemical attacks.

Alkali-Silica Reaction

An alkali-silica reaction

can occur when aggregates containing silica that is soluble in highly alkaline

solutions may react to form a solid, nonexpansive, calcium-alkali-silica

complex or an alkali-silica complex that can absorb considerable amounts of

water and expand. This can be disruptive to concrete.

Concrete that shows map or

pattern cracking and a general appearance of swelling could be a result of an

alkali-silica reaction. This can be avoided by using concrete that contains

less than 0.60% alkali.

Various Chemical Attacks

Concrete is fairly

resistant to chemical attack. For a substantial chemical attack to have

degrading effects of a measurable nature, a high concentration of the chemical is

required. Solid dry chemicals are rarely a risk to concrete. Chemicals that are

circulated in contact with concrete do the most damage.

When concrete is subjected

to aggressive solutions under positive differential pressure, the concrete is

particularly vulnerable. The pressure can force aggressive solutions into the

matrix. Any concentration of salt can create problems for concrete structures.

Temperature plays a role in concrete destruction with some chemical attacks.

Dense concrete that has a low water-cement ratio provides the greatest

resistance. The application of an approved coating is another potential option

for avoiding various chemical attacks.

Code Consideration

When concrete joints are created, they must be located

in a manner that will not have an adverse effect on the strength of the

concrete in which they are installed.

Sulfate

Situations

A sulfate attack on

concrete can occur from naturally occurring sulfates of sodium, potassium,

calcium, or magnesium. These elements can be found in soil or in groundwater.

Sulfate ions in solution will attack concrete. Free calcium hydroxide reacts

with sulfate to form calcium sulfate, also known as gypsum. When gypsum combines

with hydrated calcium aluminate it forms calcium sulfoaluminate. Either

reaction can result in an increase in volume. Additionally, a purely physical

phenomenon occurs where the growth of crystals of sulfate salts disrupts the

concrete. Map and pattern cracking are signs of a sulfate attack. General

disintegration of concrete is also a signal of the occurrence.

Sulfate attacks can be

prevented with the use of dense, high-quality concrete that has a low

water-cement ratio. A Type V or Type II cement is a good choice. If pozzolan is

used, a laboratory evaluation should be done to establish the expected

improvement in performance.

Code Consideration

Unless otherwise authorized, all bending of

reinforcement material for concrete must be done while the material is cold.

Before you can correct problems with concrete

installations, you must identify the problem. See the table below for reference

material in completing this task.

Relating Symptoms to Causes of Distress and

Deterioration of Concrete

POOR WORKMANSHIP

Poor workmanship accounts

for a number of concrete issues. It is simple enough to follow proper

procedures, but there are always times when good practices are not employed.

The solution to poor workmanship is to prevent it. This is much easier said

than done. All sorts of problems can occur when quality workmanship is not

assured and some of the key causes for these problems are as noted below:

• Adding too much water to

concrete mixtures

• Poor alignment of

formwork

• Improper consolidation

• Improper curing

• Improper location and

installation of reinforcing steel members

• Movement of formwork

• Premature removal of

shores or restores

• Settling of the concrete

• Settling of subgrade

• Vibration of freshly

placed concrete

• Adding water to the

surface of fresh concrete

• Miscalculating the timing

for finishing concrete

• Adding a layer of

concrete to an existing surface

• Use of a tamper

• Jointing

All concrete forms for the

placement of concrete need to be inspected closely. This includes confirming

that the forms are properly built and that all needed reinforcement is in place

(see Figure below).

CORROSION

Corrosion of steel reinforcing

members is a common cause of damage to concrete. Rust staining will often be

present during a visual inspection if corrosion is at work. Cracks in concrete

can tell a story. If they are running in straight lines, like parallel lines at

uniform intervals that correspond with the spacing of steel reinforcement

materials, corrosion is probably at the root of the problem. In time,

spalling will occur. Eventually, the reinforcing material will become exposed

to a visual inspection.

Code Consideration

Unless otherwise authorized, it is a code violation to

weld crossing bars that will reinforce concrete.

Techniques for stopping, or controlling, corrosion

include the use of concrete with low permeability. In addition, good

workmanship is needed. Some tips to follow include:

• Use as low a concrete slump as practical.

• Cure the concrete properly.

• Provide adequate concrete cover over reinforcing

material.

• Provide suitable drainage.

• Limit chlorides in the concrete mixture.

• Pay special attention to any protrusions, such as

bolts and anchors.

DESIGNER ERRORS

Designer errors are divided

into two categories: those that are a result of inadequate structural design

and those that are a result of a lack of attention to relatively minor design

details. In the case of structural design errors, the result can be anticipated

and will generally result in a structural failure.

Identifying structural

design mistakes concentrates on two types of symptoms, spalling and cracking.

Spalling indicates excessively high compressive stress. Cracking and spalling

can also indicate high torsion or shear stresses. High-tensile stresses will

cause cracks. Petro- graphic analysis and strength testing of concrete is

required if any of the concrete elements are to be reused after such failures.

The best prevention requires careful attention to detail. Design calculations

should be checked thoroughly. Flaws in design details account for most of these

types of problems. See the following list for examples of design factors to

consider:

• Poor design details

• Abrupt changes in section

• Insufficient reinforcement at reentrant corners and

openings

• Inadequate provision for deflection

• Inadequate provision for drainage

• Insufficient travel in expansion joints

• Incompatibility of materials

• Neglect of creep effect

• Rigid joints between precast units

• Unanticipated shear stresses in piers, columns, or

abutments

• Inadequate joint spacing in slabs

ABRASION

Abrasion damage can occur from waterborne debris, which

typically rolls and grinds against concrete when it is in the water and in

contact with concrete structures. Spillway aprons, stilling basin slabs, and

lock culverts and laterals are the most likely types of structures to be

affected by abrasion. The reason for this is often a result of poor hydraulic

design. Another cause for abrasion can be a boat hull hitting a concrete

structure.

Code Consideration

When groups of reinforcing bars are bundled together as

a reinforcement device for concrete, the bundle must not contain more than four

bars.

When abrasion occurs, concrete structures tend to wind

up with a smooth surface. Long, shallow grooves in a concrete surface and

spalling along monolith joints indicate abrasion. The three major factors in

avoiding abrasion damage are design, operation, and materials.

For prevention strategies, review the list of tips

below:

• Use hydraulic model studies to test designs.

• A 45 degree fillet installed on the upstream side of

the end sill results in a self-cleaning stilling basin.

• Recessing monolith joints in lock walls and guide

walls will minimize stilling basin spalling caused by barge impact and

abrasion.

• Balanced flows should be maintained into basins by

using all gates to avoid discharge conditions where eddy action is prevalent.

• Periodic inspections are needed to locate the presence

of debris.

• Basins should be cleaned periodically.

• All materials used must be tested and evaluated.

• Install abrasion-resistant concrete.

• Fiber-reinforced concrete should not be used for

repairing stilling basins or other hydraulic structures subject to abrasion.

• Coatings that produce good results against abrasion

include polyurethanes, epoxy-resin mortar, furan-resin mortar, acrylic mortar,

and iron aggregate toppings.

CAVITATION

Cavitation erosion is a result of complex flow

characteristics of water over concrete sur- faces. For damage to occur, the

rate of water flow normally needs to exceed 40 feet per second. Fast water and

irregular surface areas of concrete can result in cavitation. Surface

irregularity and water speed create bubbles. The bubbles are carried

downstream and have a lowered vapour pressure. Once the bubbles reach a stretch

of water that has normal pressure, the bubbles collapse. The collapse is an

implosion that creates a shock wave. Once the shock wave reaches a concrete

surface, the wave causes very high stress over a small area. When this

process is repeated, pitting can occur. This type of cavitation has affected

concrete spillways and outlet works of many high dams. Prevention has to do

with design, materials, and construction practices. The following list

highlights some of the key considerations:

• Include aeration in a hydraulic design.

• Use concrete designed with a low water-cement ratio.

• Use hard, dense aggregate particles.

• Steel-fiber concrete and polymer concrete can aid in

the fight against cavitation.

• Neoprene and polyurethane coatings can assist in the

fight against cavitation; however, coatings are rarely used as they might

prevent the best adhesion to concrete. Any rip or tear in the coating can cause

a complete stripping of the coating over time.

• Maintain approved construction practices.

Code Consideration

Bundle reinforcing bars must be enclosed within either

stirrups or ties.

FREEZING AND THAWING

Freezing and thawing during

the curing of concrete is a serious concern. Each time the concrete freezes, it

expands. Hydraulic structures are especially vulnerable to this type of damage.

Fluctuating water levels and under-spraying conditions increase the risk. Using

deicing chemicals can accelerate damage to concrete with resultant pitting and

scaling. Core samples will probably be needed to assess the damage.

Prevention is the best

cure. Provide adequate drainage, where possible, and work with low water–cement

ratio concrete. Use adequate entrained air to provide suitable air-void systems

in the concrete. Select aggregates best suited for the application, and make

sure that concrete cures properly.

SETTLEMENT AND MOVEMENT

Settlement and movement can

be the result of differential movement or subsidence. Concrete is rigid and

cannot stand much differential movement. When it occurs, stress cracks and

spall are likely to occur. Subsidence causes entire structures or single

elements of entire structures to move. If subsidence is occurring, the concern

is not cracking or spalling; the big risk is stability against overturning or

sliding.

A failure via subsidence is

generally related to a faulty foundation. Long-term consolidations, new

loading conditions, and related faults are contributors to subsidence.

Geotechnical investigations are often needed when subsidence is evident.

Cracking, spalling,

misaligned members, and water leakage are all evidence of structure movement.

Specialists are normally needed for these types of investigations.

Code Consideration

Spiral reinforcement for cast-in-place concrete must not

be less than 3/8 in. in diameter.

SHRINKAGE

Shrinkage is caused when

concrete has a deficient moisture content. It can occur while the concrete is

set or after it is set. When this condition happens during setting, it is

called plastic shrinkage; drying shrinkage happens after the concrete has been set.

Plastic shrinkage is

associated with bleeding, which is the appearance of moisture on the surface of the concrete. This is usually caused by the settling of heavier components in a

mixture. Bleed water typically evaporates slowly from the surface of concrete.

When evaporation occurs faster than water is supplied to the surface by

bleeding, high-tensile stresses can develop. This stress can lead to cracks on

the concrete surface.

Cracks caused by plastic

shrinkage usually occur within a few hours of concrete placement. These

cracks are normally isolated and tend to be wide and shallow. Pattern cracks

are not generally caused by plastic shrinkage.

Code Consideration

Spacing requirements for shrinkage and temperature

reinforcement must be spaced no farther apart than five times a slab’s

thickness and no farther apart than 18 in.

Weather conditions

contribute to plastic shrinkage. If the conditions are expected to be conducive

to plastic shrinkage, protect the pour site with windbreaks, tarps, and similar

arrangements to prevent excessive evaporation. In the event that early cracks

are discovered, revibration and refinishing can solve the immediate problem.

Drying shrinkage is a

long-term change in the volume of concrete caused by the loss of moisture. A

combination of this shrinkage and restraints will cause tensile stresses and

lead to cracking. The cracks will be fine and the absence of any indication of

movement will exist. The cracks are typically shallow and only a few inches

apart. Look for a blocky pattern to the cracks. They can be confused with

thermally induced deep cracking, which occurs when dimensional change is

restrained in newly placed concrete by rigid foundations or by old lifts of concrete.

To

reduce drying shrinkage, try the following precautions:

• Use less water in concrete.

• Use larger aggregate to minimize paste content.

• Use a low temperature to cure concrete.

• Dampen the subgrade and the concrete forms.

• Dampen aggregate if it is dry and absorbent.

• Provide adequate reinforcement.

• Provide adequate contraction joints.

FLUCTUATIONS IN TEMPERATURE

Fluctuations in temperature

can affect shrinkage. The heat of hydration of cement in large placements can

present problems. Climatic conditions involving heat also affect concrete; for

example, fire damage, while rare, can also contribute to problems associated

with excessive heat.

Code Consideration

The code allows one to assume that the ends of columns

built integrally with a structure will remain fixed. This assumption is used

while computing gravity load moments on columns

Hydration of concrete can

raise the temperature of freshly placed concrete by up to 100 degrees. Rarely

is the temperature increase consistent throughout the concrete, which can

generate problems such as shallow and isolated cracks. How can this be avoided?

See the tips below:

• Use low-heat cement.

• Pour concrete at the

lowest reasonable temperature.

• Select aggregates with

low moduli of elasticity and low coefficients of thermal expansion.

External temperature

changes can result in cracking that will appear as regularly spaced cracks.

There may be spalling at expansion joints. Using contraction and expansion

joints can help prevent this damage.

There are many potential

causes for concrete failure. Extended education, experience, and scientific

testing is often required to clearly identify these causes. There is always

more to learn. Keeping an open mind and immersing yourself in the components of

concrete is the best route to success.

If you find

This information is helpful, please share it.

Thanks! For reading the article...

\

No comments:

Post a Comment