What Is Lintel Beam?

The lintel is a horizontal flexible member that has openings in

the walls for doors, windows, ventilators, cabinets, etc. Above the opening, a

masonry wall is transferred so that the frames of the doors, windows, etc. are

not mounted unnecessarily. The end bearings for the lintel should be at least

200 mm.

Bearing of Lintel

The length of the lintel bearing provided by the following 4

cases.

• Height of lintel beam

• 150 mm is minimum

• 1/10th to 1/12th of span of the lintel.

• The width of the lintels is equal to the width of the wall.

Always

provide adequate support for the ends of the lintels. The manufacturer's recommendations

should be followed, but the standard test is 150mm (6") at each. If you do

not provide sufficient results, the lintel will fail under loads.

What

is the length of the lintel?

(Or)

How

wide is the structural opening?

·

Measure the size of

the structural opening therefore the clear span between the masonry supports.

·

Add 200mm (200mm is

an example) minimum bearing to each end.

Example lintel length = 200 + 1200 + 200

= 1600mm

ALSO READ: How To Calculate Steel Quantity Of Lintel Beam - Bar Bending Schedule

Types of Lintels Based on Construction

Materials

1.

Wooden Lintels

2.

Brick Lintels

3.

Stone Lintels

4.

Reinforced Brick

Lintels

5.

Concrete Lintels

a)

Plain Concrete

Lintels

b) Reinforced Concrete Lintels

I.

(b) Precast Lintels

II.

(b) Cast in Situ

Lintels

6.

Steel Lintels

·

Standard Cavity

Steel Lintels

·

Short Outer Leaf

Steel Lintels

·

Wide Inner Leaf

Steel Lintels

·

Wide Outer Leaf

Steel Lintels

7.

Specialist Lintels –

Catnic

8.

Cavity Lintels

In

this article, we will discuss on main types of lintel based on materials

1. Timber Or Wooden Lintel

In

the old days of construction, wooden lintels were often used. But nowadays

they are being replaced by many modern techniques, though they are still used

in hilly areas. The main drawbacks with trees are high cost and low durability

and vulnerability to fire.

If

the length of the opening is greater, it is provided by attaching several

pieces of wood with the help of the steel bolts shown in the figure below As

for the wide walls, it was made up of two pieces of wood placed at a distance

with the help of packing pieces made of wood. Sometimes, these are reinforced

by providing mild steel plates at the top and bottom, called flitch lintels.

It has some other

drawbacks-

1.

It is less durable.

2.

The wood is

flammable so it is prone to fire.

3.

These lindels are

structurally weak.

4.

Without proper

ventilation, wood is bound to rot.

2. Brick Lintels

These

are used to small span openings (less than a meter) with light loading. They

usually have bricks, which are usually placed at the end and occasionally at

the edge.

The brick lintel is built on a temporary wooden support (i.e., centrally

functioning) called the Turning Piece. Bricks with frogs are more suitable for building

lintels because they form dents when bordered, and therefore have higher

cutting resistance at the end joints (higher strength). The structure formed by

the use of frog bricks is called ‘jockey brick lintel’.

The

following points should be given due consideration:

Brick

lintels are the most frequently used applications of construction in brickwork. Steel bars (1:3) supplied on the tension side of the bricklayer and rich

cement fill the construction joints in which the steel wires are placed.

The

width of the joints should be at least 3 times the diameter of the

reinforcement bar applied. The bricks used should be of good quality.

This

type of lintel can be used for gaps up to 2500 mm and the thickness can be 100

mm, 200 mm..

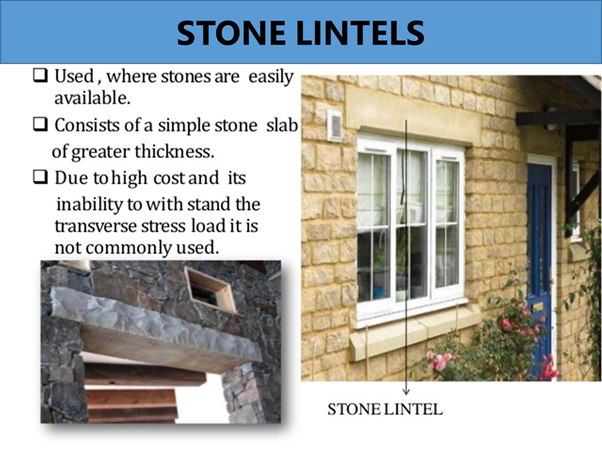

3. Stone Lintel

stone

bits in rectangular shape can be used as a lintel. This type of lintel is

mainly used in this area where there is good access to the stone. On the off

chance that the length of the opening is long, by that time, at any rate, two

bits of wood are attached to give the lintel everything that is considered to

be openings. They are only used in mountainous buildings because they weigh too

much and other materials are not available for construction. Its use is

basically tied to stone masonry structures. Stone lintels must be used in

accordance with the characteristic layout. The thickness of the stone lintel is

a significant factor in its design.

As thumb rule, the thickness is assumed to be 40 mm. The span length

should be 300mm and the minimum thickness 80 mm. This type of lintel will be

firm and strong.

There

are also a few drawbacks of the stone lintel.

·

Its high cost and

secondly its an inability to withstand excessive transverse stress.

·

Due to the weak

tensile strength they are not used in buildings subject to vibratory loads

structure.

·

Transportation is a

very complex task so it is difficult to tranfer them to cities.

4.

Reinforced Brick Lintels

The

problems for brick lintels are heavier loads and more substantial span lengths.

These can be overcome by using the reinforcing bars. So reinforced brick

lintels provide more support than brick lintels. The depth of the reinforced

brick lintels is equal to 100 mm. or a multiple of 100 mm (or one brick

thickness).

The

arrangement of the bricks should be such that there is sufficient space between

the adjacent bricks for the insertion of light steel bars as reinforcement.

After inserting bars, the remaining gap is filled with a 1: 3 cement mortar. 6

mm bars are used as vertical stirrups at every 3rd vertical component. 8 to 10

mm bars placed at the bottom are used as primary reinforcement.

5.

Steel Lintels

Steel lintels are suitable where

exaggerated loads are heavy and opening spaces are large. Steel lintels are

desirable when lintel depth plays an important role because the depth of

reinforced concrete lintels cannot be ignored by the designer due to the high

loads.

These lintels use profiled

sections or beams made of rolled steel or profiled sections individually or in

combination with two or three units. Depending on requirements, Lintel can be

one division or two or more combinations. The single steel joist can be

embedded in concrete or covered with a stone face to maintain the same width of

the wall. The combination of two or more units is placed side by side and

positioned by the pipe separator. Water supply is provided for ten days in all

cases.

It has several things note:

·

Steel lintels can be

used to support heavier loads on more important sections without the need to

replace or reinforce.

·

Steel lintels are

subject to rust, corrosion or corrosion.

·

Steel lintels are

very practical and less labour intensive.

6. Reinforced Cement Concrete Lintel

Currently, reinforced

concrete lintels are the most common in use. In this way, reinforcement is used

to overcome the low compliance problem in concrete. They are built into today’s

structures. They are suitable for high loads and large opening. Their thickness

is kept up to 8 centimetres per meter. RCC lintels may be precast or cast-in-situ.

Generally, precast

reinforced cement concrete lintels are used when the lintel gap is small. The

width of the lintel should be equal to the width of the wall. The depth of the

lintel depends on the length of the span and the amount of loading.

Concrete, although strong

in compression, is brittle to tensile stress, so key reinforcement bars are

used below to resist tensile stress. Half of these bars are tied at the ends.

Cut stirrups are provided to withstand transverse shear stress. Typically,

cement, sand and aggregates are mixed in the ratio of 1: 2: 4 to form a cement

concrete mortar.

There are a few benefits to

this lintel:

·

They are durable,

tough and strong.

·

Reinforced concrete

lintel has fire-resistant properties.

·

They are economical

and easy to build.

·

The main advantage

of RCC lintels is that they can be modified to fit any size and shape.

FAQs

Uses of lintel beam

· The

purpose of the lintel beam

· These

beams are used to support the walls above openings such as windows and doors.

· For

the safety of windows and doors, these beams are provided.

· These

beams are provided to withstand the loads coming from the blocks or bricks

above.

· It

is provided to shift its loads to the side walls.

· Lintels

are sometimes used as decorative architectural elements.

What

are the types of lintel in construction?

1.

Wooden Lintels

2.

Brick Lintels

3.

Stone Lintels

4.

Reinforced Brick

Lintels

5.

Concrete Lintels

a)

Plain Concrete

Lintels

d) Reinforced Concrete Lintels

III.

(b) Precast Lintels

IV.

(b) Cast in Situ

Lintels

6.

Steel Lintels

·

Standard Cavity

Steel Lintels

·

Short Outer Leaf

Steel Lintels

·

Wide Inner Leaf

Steel Lintels

·

Wide Outer Leaf

Steel Lintels

7.

Specialist Lintels –

Catnic

8.

Cavity Lintels

Must

read: Know

the Difference between Formwork, Shuttering, Centering, and Staging

If you find

This information helpful please share it.

Thanks! For reading the article.

No comments:

Post a Comment