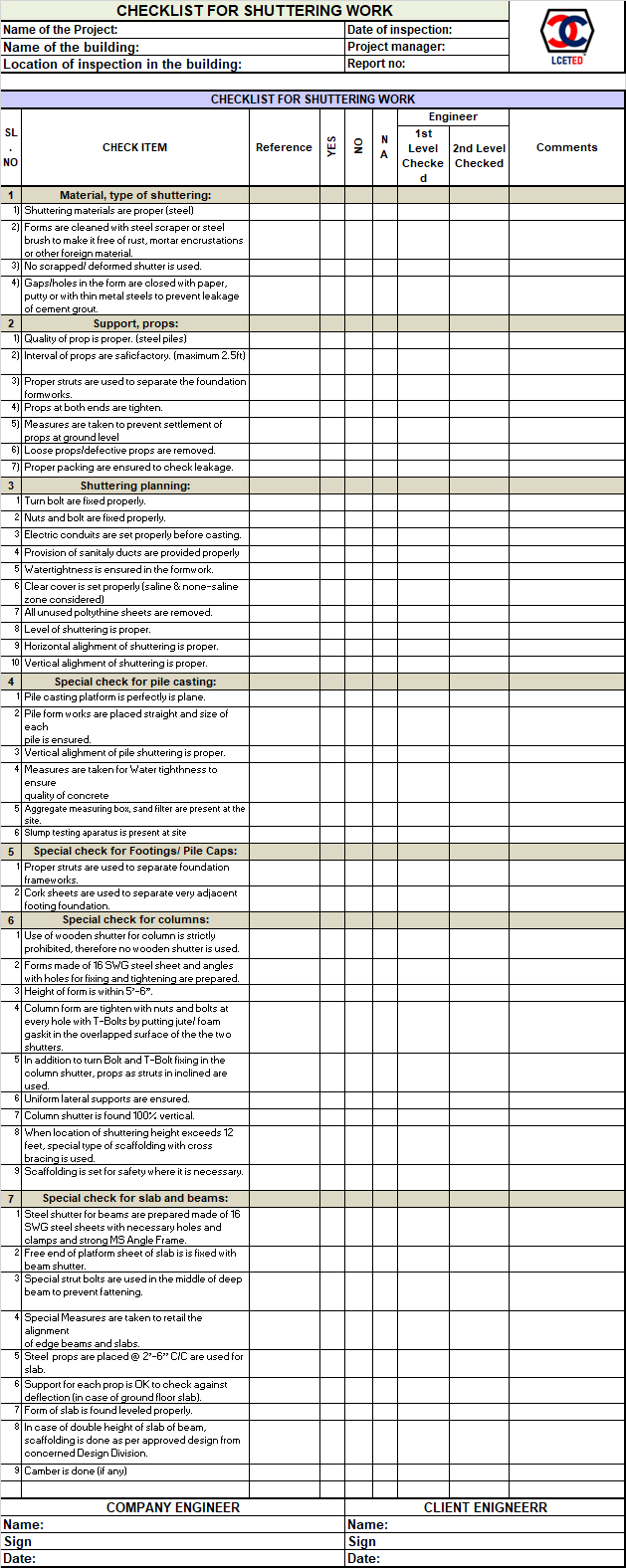

Excel Sheet checklist for Formwork

shuttering in concrete construction is used as a mould for a structure into

which fresh concrete is poured only to harden later.

The formwork is not

suitable for concrete and work is done at height, which may pose a safety

issue. Concrete formwork is a temporary support structure for concrete that

holds it in position and shape until the concrete hardens on the construction

site. The quality of concrete is affected by improper alignment of formwork,

lack of leakage proof etc. Proper storage of concrete formworks is also required

for cost saving of the project.

Also Read: Know the Difference between Formwork, Shuttering, Centering, and Staging

CHECKLIST FOR SHUTTERING WORK

Material, type of shuttering:

1) Shuttering

materials are proper (steel)

2) Forms

are cleaned with a steel scraper or steel brush to make them free of rust, mortar

encrustations or other foreign material.

3) No

scrapped/ deformed shutter is used.

4) Gaps/holes

in the form are closed with paper, putty or with thin metal steels to prevent

leakage of cement grout.

Support, props:

1) Quality

of the prop is proper. (steel piles)

2) Interval

of props are saficfactory. (maximum 2.5ft)

3) Proper

struts are used to separate the foundation formworks.

4) Props

at both ends are tightened.

5) Measures

are taken to prevent settlement of props at ground level

6) Loose

props/defective props are removed.

7) Proper

packing are ensured to check leakage.

Shuttering planning:

1) Turn

bolt are fixed properly.

2) Nuts

and bolt are fixed properly.

3) Electric

conduits are set properly before casting.

4) Provision

of sanitaly ducts are provided properly

5) Watertightness

is ensured in the formwork.

6) Clear

cover is set properly (saline & none-saline zone considered)

7) All

unused poltythine sheets are removed.

8) Level

of shuttering is proper.

9) Horizontal

alighment of shuttering is proper.

10) Vertical

alighment of shuttering is proper.

Special check for pile casting:

1) Pile

casting platform is perfectly is plane.

2) Pile

form works are placed straight and size of each pile is ensured.

3) Vertical

alighment of pile shuttering is proper.

4) Measures

are taken for Water tighthness to ensure quality of concrete

Special check for Footings/ Pile Caps:

1) Proper

struts are used to separate foundation frameworks.

2) Cork

sheets are used to separate very adjacent footing foundations.

Special check for columns:

1) Use

of wooden shutter for column is strictly prohibited, therefore no wooden

shutter is used.

2) Forms

made of 16 SWG steel sheet and angles with holes for fixing and tightening are

prepared.

3) Height

of form is within 5’-6”.

4) Column

form are tightened with nuts and bolts at every hole with T-Bolts by putting

jute/ foam gaskit in the overlapped surface of the the two shutters.

5) In

addition to turn Bolt and T-Bolt fixing in the column shutter, props as struts

in inclined are used.

6) Uniform

lateral supports are ensured.

7) Column

shutter is found 100% vertical.

8) When

location of shuttering height exceeds 12 feet, special type of scaffolding with

cross bracing is used.

9) Scaffolding

is set for safety where it is necessary.

Also use: How To Calculate Area Of Shuttering And Centering For Staircase?

Special check for slab and beams:

1) Steel

shutter for beams are prepared made of 16 SWG steel sheets with necessary holes

and clamps and strong MS Angle Frame.

2) Free

end of platform sheet of slab is is fixed with a beam shutter.

3) Special

strut bolts are used in the middle of deep beam to prevent fattening.

4) Special

Measures are taken to retail the alignment of edge beams and slabs.

5) Steel

props are placed @ 2’-6’’ C/C are used for slab.

6) Support

for each prop is OK to check against deflection (in case of ground floor slab).

7) Form

of slab is found levelled properly.

8) In

case of double height of slab of beam, scaffolding is done as per approved

design from concerned Design Division.

9) Camber

is done (if any)

To fulfill your dream homes with the best technology and designs

ReplyDeletehouse construction companies in hyderabad