To determine the California Bearing Ratio (CBR) of the subgrade soil by conducting a load penetration test in the laboratory.

Theory and Scope

California Bearing Ratio

(CBR) test originally developed by the California Division of Highways (U.S.A.)

is one of the most commonly used methods

to evaluate the strength of subgrade soil for the design of pavement thickness. CBR value as defined by IS: 2720

(Part XVI)-1979 is the ratio of the force per unit area required to penetrate a soil mass with a circular

plunger of 50 mm diameter at the rate of 1.25 mm/minute, to that required for corresponding penetration of a

standard material.

The standard load is that load

that has been obtained from tests on a crushed stone whose CBR value is taken

to be 100 per cent. The ratio is usually determined for penetrations of 2.5 mm

and 5.0 mm. The results of this empirical test cannot be related

accurately with the fundamental properties

of the material but are useful in the design of flexible pavements.

Apparatus

Apparatus conforming to the

essential requirements of IS: 2720 (Part XVI) with the mould as per IS:

9669. The field CBR apparatus meets the

requirements of IS: 2720 (Part XXXI).

A metallic cylinder mould;

Loading machine; Perforated swell plate; Proving ring of 10 kN capacity; Two dial gauges reading to 0.01 mm; 4.75 mm and

20 mm IS sieves; Steel cutting collar; Penetration plunger; Metal rammers; Mixing bowl, Spacer disc;

Surcharge weights; Straight edge; Scales; Soaking tank; Drying oven; Filter paper; Dishes and Calibrated measuring

jar.

Description of apparatus as per IS:

9669-1980

Mould consists of a gunmetal or steel cylinder of 150 mm internal diameter and 175 mm height; provided

with a detachable metal extension collar of 50 mm in height. It also has a detachable perforated base plate of 10 mm thickness. The perforations in the base plate

do not exceed 1.5 mm in diameter.

Loading machine with a

capacity of at least 50 kN and equipped with a movable head or base that can

travel vertically at a uniform rate of

1.25 mm/minute. Complete with load indicating device. There are two types of test frames:

1. Hand-operated load frame of capacity 50 KN.

2. Motorised

press or load frame of capacity 50 KN.

In place of dial gauge and

proving ring assembly, electronic instrumentation is also available. Typical

CBR test loading machines are

illustrated in Figs. below

A spacer disc is a metal disc

of 148 mm in diameter and 47.7 mm in height. The spacer disc has a groove on

one side so that a handle can be screwed

to facilitate its lifting.

Metal rammer of 2.6 kg

weight with a drop of 310 mm (or) 4.89 kg weight with a drop of 450 mm.

Steel cutting collar of 60

mm total height which can fit flush with the mould; Penetration plunger having

a diameter of 50 mm and at least 100 mm

length.

Surcharge weights One

annular metal weight and several slotted weights 2.5 kg each and 147 mm in diameter with a 53 mm diameter central

hole.

The penetration plunger has

a diameter of 50 mm and at least 100 mm in length.

Procedure

The method can be used for

the determination of CBR of undisturbed and remoulded/compacted soil specimens

in soaked as well as in unsoaked states. In the case of a remoulded soil test, the

specimens may be compacted either

statically or dynamically.

Part 1: Preparation of test specimen

Prepare

two specimens of the required type as follows:

Step

1:

Undisturbed or natural soil specimen Attach the steel cutting edge to the mould

and push it gently into the ground till

the mould is full of soil. Remove the soil from the sides and bottom. Trim the excessive soil from top and bottom;

weigh the soil with the mould and determine its density.

Step

2:

Remoulded or compacted specimen Prepare the remoulded specimen at Proctor’s

maximum dry density or any other

density at which CBR is required. Maintain the specimen at optimum moisture

content or the field moisture as

required. The material taken for remoulded specimen should pass the 20 mm IS sieve and be retained on the 4.75 mm IS sieve. In

case the soil contains larger than 20 mm size particles, it should be replaced by an equal amount of

material passing a 20 mm sieve but retained in a 4.75 mm sieve. The remoulded samples are compacted either

statically or dynamically.

A) Statically

compacted specimen

1. Calculate the weight of the soil at the required

water content for the desired density after

compaction such that it fills the mould (excluding collar);

W =

desired dry density × (1+w) V

Where, W = Weight of the wet soil

w =

desired water content

V = volume of the specimen in the mould = 2250 cm3 (as

per the mould available in the laboratory)

2. Fix the extension collar to the mould and clamp it to

the base plate. Take the weight W

(calculated as above) of the soil mixed thoroughly with water and place

it in the mould.

3. Fill the mould with soil, gently pressing it with your hands so that it does not spill out of the mould.

4. Place a coarse filter paper over the levelled soil

surface and then insert the spacer disc.

5. Place the mould assembly on the pedestal of the static

loading machine and compact the soil by

pressing the displacer disc till the disc is flush with the top of the mould.

Keep the load for some time and then

release the load and remove the displaced disc.

B) Dynamically

compacted specimen

1. Take about 4.5 to 5.5 kg

of granular soils sieved through a 20 mm IS sieve in a mixing pan and add water to the soil in the quantity

such that the moisture content of the specimen is either equal to field moisture content or OMC

(Optimum Moisture Content) as desired.

Mix together the soil and water uniformly.

2. Clamp the mould along with the extension collar to

the base plate. Insert the spacer and discover the base with the hole on the bottom side. Place a coarse filter paper on the

top of the spacer disc.

3. Compact the soil-water mix in the mould using either

light compaction or heavy compaction.

For light compaction, compact the soil into three equal layers, each layer

being given 55 blows with the rammer

weighing 2.6 kg dropping through 310 mm. For heavy compaction compact the soil in five layers, 56

blows to each layer by the 4.89 kg rammer dropping through 450 mm. After each layer compacted surface should be

scratched before adding soil for the subsequent layer.

4. Remove the extension collar and trim off the excess

soil by a straight edge.

5. Turn the mould upside down and remove the base plate,

the displacer disc and the filter paper.

6. Weigh the mould with compacted soil and determine the

bulk and dry densities.

7. Invert the mould and place a coarse filter paper on

the top of the compacted soil (collar side) and clamp the perforated base plate onto it so that the soil is

in contact with the filter paper in the

base.

The test may be conducted for both soaked as well as

unsoaked conditions.

Part 2: For the CBR test on the specimen

soaked in both cases of compaction, soak the prepared specimen as described in Step 1 as follows;

in the case of the unsoaked test move to Step 3.

Step

1:

Weigh the sample excluding the base plate and spacer disc; put a filter paper on the

top of the soil and the perforated plate

on the top of the filter paper.

Step

2:

Place annular weights to produce a surcharge equal to the weight of base material

and pavement expected in actual

construction; the surcharge weight may vary from 2.5 to 5 kg. Immerse the mould assembly and weights in a water tank for 4

days. Each 2.5 kg weight is equivalent to 70 mm construction. A minimum of two

weights should be placed.

Step

3:

Remove the mould from the tank and drain off the water from the sample hold it in a vertical position for about 15 minutes.

Step

4:

Weigh the sample again to calculate the percentage of water absorbed.

Part 3: Test the specimen following the normal procedure

Step

1:

Place the mould assembly containing the specimen along with the base plate and

surcharge weight of 2.5 kg on the top surface of the soil on the penetration test

machine.

Step

2:

Install the proving ring assembly and penetration plunger onto the loading

machine. Seat the plunger at the centre

of the specimen with the smallest possible load, but in no case in excess of 4

kg so that full contact of the plunger

on the sample is established as shown in Fig. below

Step

3:

Place the remainder surcharge weight (slotted weight) so that the total surcharge

weight equals 5 kg. This should be treated as a zero load position.

Step

4:

Mount the dial gauge with the tip of its stem resting on the collar to measure

the penetration; set the dial gauges to

read zero.

Step

5:

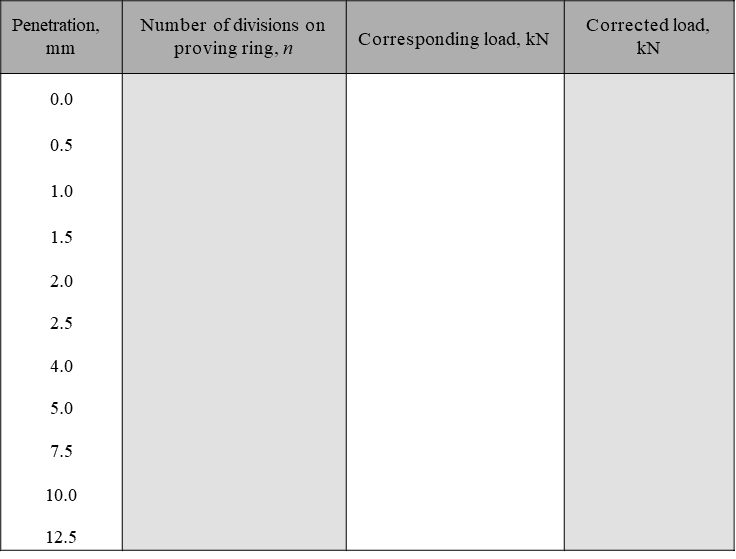

Apply load so that penetration rate is 1.25 mm/minute. Record the load at

penetrations of 0.0, 0.5, 1.0, 1.5, 2.0, 2.5, 4.0, 5.0, 7.5, 10.0 and 12.5 mm.

In case the load starts decreasing before 12.5 mm penetration, record the maximum load and the

corresponding penetration value.

Step

6:

Detach the mould from the loading assembly and take about 20 to 50 g of soil

from the top 30mm layer and determine

the moisture content.

At least three specimens should be

tested on each type of sample. The maximum permissible variation should be within the limits given

below.

|

CBR, percent |

Maximum permitted variation, percent |

|

<

10 |

3 |

|

10−30 |

5 |

|

30−60 |

10 |

|

>

60 |

Not

Significant |

|

CBR, per cent |

The maximum permitted variation, per cent |

Part 4: Computation of test results

Step

1:

Plot the load penetration curve with the load as ordinate and penetration as

abscissa. Generally, the initial portion of the curve is concave upwards due to

surface irregularities. In such a case apply a correction. Draw tangent at the

point of the greatest slope. The point where this tangent meets the abscissa is the corrected zero reading of penetration

as illustrated in Fig. below

Typical load penetration curve

Step

2:

From the load penetration curve, determine the load value corresponding to the penetration

value at which the CBR is desired.

Step

3:

The CBR value is computed from

where PT = corrected test pressure

corresponding to the chosen penetration from the load penetration curve in MPa.

Ps =

pressure to achieve equal penetration on standard soil in MPa

In most cases, CBR

decreases as the penetration increases. The CBR values are usually calculated

for penetrations of 2.5 mm and 5 mm, and the greater of the two is adopted for

design purposes. Generally, the CBR value

at 2.5 mm is greater than that at 5 mm. However, if CBR for 5 mm penetration exceeds that for 2.5 mm, then the

test is to be repeated for checking. If the check test gives similar results, the CBR value corresponding

to 5 mm penetration is taken as the design value.

The standard loads adopted for different penetrations

for the standard material with a CBR value of 100 per cent are given in the table below.

Standard

load for different penetration values

|

Penetration, mm |

Unit standard

load, kgf/cm2 |

Total standard

load, kgf |

|

2.5 |

70 |

1350 |

|

5.0 |

105 |

2055 |

|

7.5 |

134 |

2630 |

|

10.0 |

162 |

3180 |

|

12.5 |

183 |

3600 |

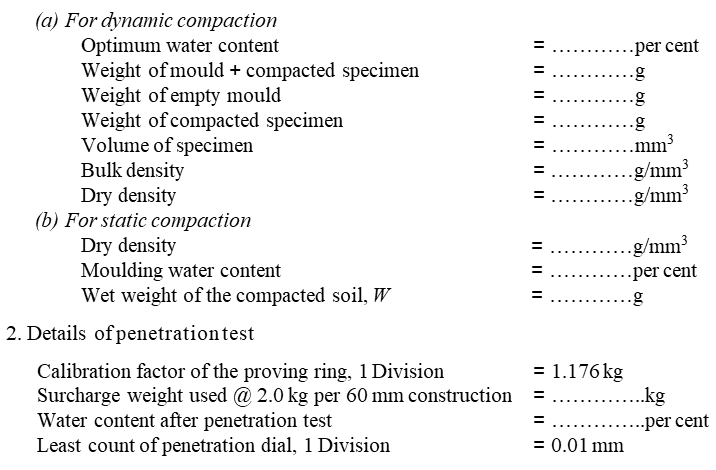

Observations and Calculations

1.

Details of the sample

|

Sample

details |

Location |

|

|

|

Type of sample |

Undisturbed/Remoulded |

|

|

|

Compaction of

specimen |

Static/Dynamic |

|

|

|

Type of

compaction |

Light / Heavy |

|

|

|

Condition of

soaking |

Soaked /

Un-soaked |

|

|

|

Period of

soaking |

96 hours |

|

|

|

Surcharge

weight, |

|

|

|

|

Dry unit weight |

|

|

|

|

Weight of

material coarser than 20 mm replaced |

|

|

|

|

The water content of the compacted sample |

per cent |

|

|

|

Sample details |

Location |

|

|

CBR at 2.5 mm penetration = _________

CBR at 5 mm penetration = __________

CBR of sample (design value) =__________

The average CBR value of three test specimens is

reported as the CBR value of the sample.

Precautions

1. The holes of the base plate of the mould should not

be blocked.

2. The surcharge weight should be aligned with the plunger

so that the plunger penetrates freely into the soil sample.

Discussion

California Bearing Ratio is

an empirical value that can be used in the design of flexible pavements. Tests

are carried out on natural or compacted

soils in water soaked or unsoaked conditions and the results so obtained are compared with the curves of the standard test

to have an idea of the soil strength of the subgrade soil.

The CBR is a measure of the resistance of a material to penetration of a standard plunger under controlled

density and moisture conditions. The

test procedure should strictly adhere if a high degree of reproducibility is

desired.

The harder the surface, the

higher will be the CBR value. A CBR of 3 may represent tilled farmland, a CBR of 4.75 the turf or moist clay, while

moist sand may have a CBR of 10. High-quality crushed rock has a CBR of over 80. The standard material for this

test is crushed California limestone which has a value of 100.

Design curves developed by

Road Research Laboratory, UK have been adopted by Indian Road Congress IRC: 37. Depending upon the estimated traffic

volume the thickness of the base course and sub-base course can be determined from their respective CBR

values. The range of CBR values for various types of soils is listed in the Table below

Range of CBR values for

various types of soils

What is the CBR test used for?

California bearing ratio

test (CBR) is defined as the ratio force per unit area of penetration test for

the amount of the subgrade strength of roads and sidewalks. The results

obtained from these tests are used along with empirical curves to determine the constituent layers and thickness of the pavement.

NATIONAL

STANDARDS

IS:460 (Parts 1 and 2)-1985; Specification for Test Sieves.

IS:2386 (Part 1)-1963; Methods of Test for Aggregates for Concrete: Part-I

Particle Size and Shape (with Amendment

No. 2).

IS:2386 (Part 3)-1963; Specific Gravity, Density, Voids, Absorption and Bulking.

IS:2386 (Part 4)-1966: Methods of Test for Aggregates for Concrete: Part-IV-

Mechanical Properties (Crushing Value,

Aggregate Impact Value, Abrasion, Polished Stone, Crushing Strength) (with Amendment No. 3).

IS:2386 (Part 50) − 1963; Soundness.

2430−1996

(1st Revision): Methods for Sampling of Aggregates for Concrete.

IS:2720 (Part-XVI)-l 979; Methods of Test for Soils (Lab determination of CBR).

IS

5640−1970: Method of Test for Determining Aggregate Impact Value of Soft Coarse

Aggregate.

IS:6241- 1971; Method of Test for Determining Stripping Value of Road

Aggregates.

IS:6579-1981 (1st Revision); Specifications for Coarse Aggregate for Water Bound

Macadam

(Amendment

No.1)

REFERENCES

Gambhir,

M. L., Concrete Technology, 4th Edition, McGraw-Hill Education (India), 2009.

Gambhir,

M. L. and Neha Jamwal, Building Materials: Products, Properties and Systems,

McGraw- Hill Education (India), 2011.

Millard,

R.S. (1993), Road Building in the Tropics: Transport Research Laboratory

State-of-the-Art Review 9, HMSO, London.

its aHELP FULL

ReplyDelete