WHAT

IS WAFFLE SLAB?

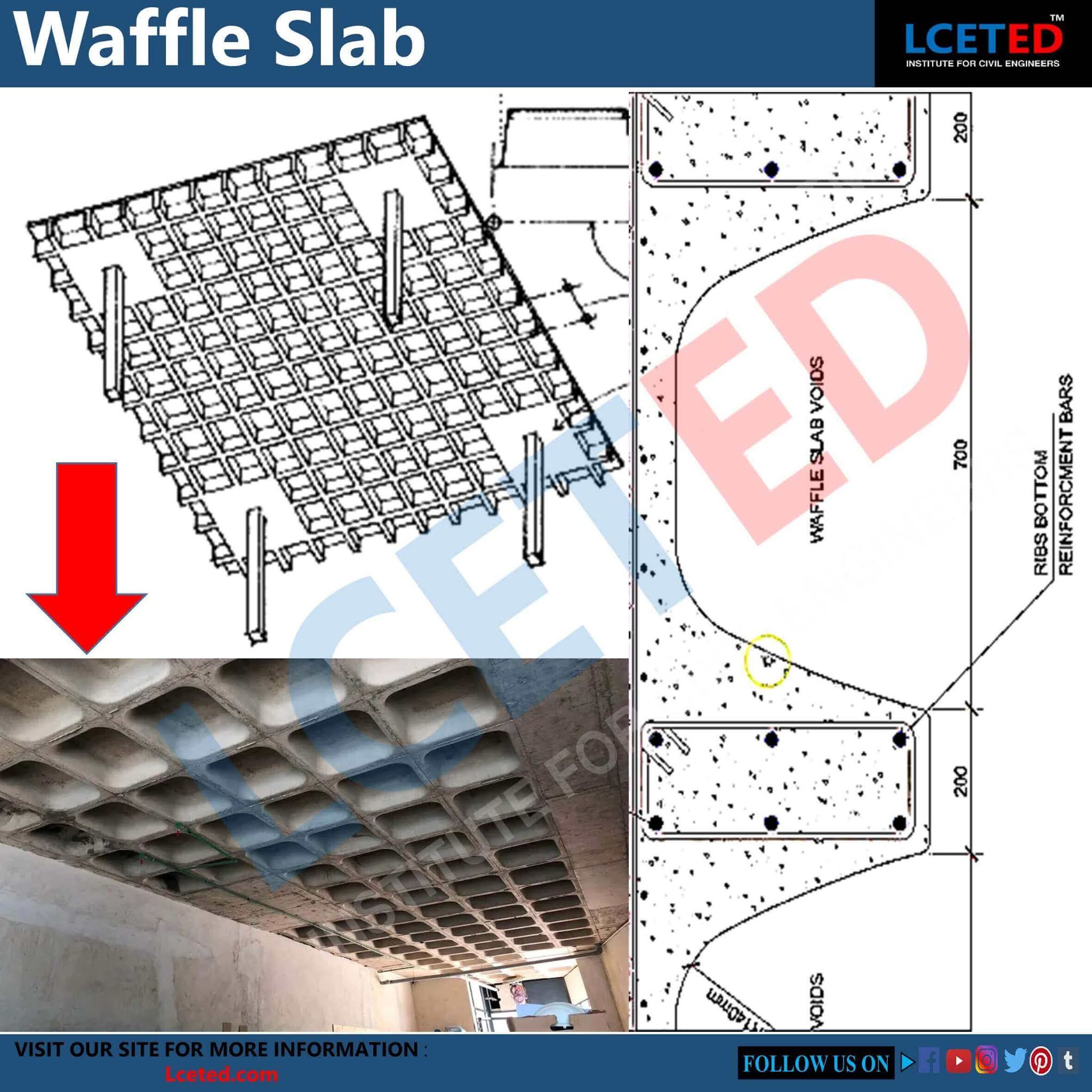

A waffle slab is a platform with a reinforced

concrete roof or floor has a square grid

with deep sides. This is also known as a grid slab. Waffle slabs at the

entrances of hotels, shopping malls and restaurants are mainly used to install

good lighting and artificial lighting.

Its main function is to withstand higher

loads and longer distances than flat floors because these systems are lighter

and therefore can be used for roofing and floor. They are also used where there

is a restriction on the depth of the beams to obtain a clear height.

Classification Of Waffle

Slab

Waffle

slab are classified into the following types based on the shape of the slabs

(PVC sheets):

1.

Triangular - pod

structure

2.

Square - pod

structure

Advantages of Waffle slabs

1.

Because these

systems are lighter in weight, waffle slabs can carry heavier loads and longer

distances than flat slabs.

2.

Suitable for intervals

of 7 m - 16 m, Longer breaks are possible with post-tensioning..

3.

Waffle slab can be

used as both ceiling and floor slab.

4.

These systems are

lightweight, so significant savings on the structure are ensured as the light

framework is required

Disadvantages

of Waffle slabs:

Waffle

slab is not used in typical construction projects.

The

casting forms or moulds required for precast units are very costly and hence

only economical when large scale production of similar units are desired.

Construction

requires strict supervision and skilled labour.

Disadvantages of Waffle

Slabs

Waffle slab was not used in

conventional construction projects.

Its is expensive, so it is

only economical when large scale production of similar units is desired.

Construction requires

rigorous supervision and skilled labour.

DESIGN OF WAFFLE SLAB

§ The design of the waffle slap depends on the total area required for the waffle slab is the main point to design a waffle slab.

§ 80 mm to 100 mm is usually thickness of waffle slab.

§ waffle slab overall depth is limited to 300 mm to 600 mm.

§ 100 mm to 200 mm is usually width of waffle slab.

§ The distance between two ribs in a row is 600 mm to 1500 mm.

§ Using rebars to reinforcement for extra strength.

§ the waffle slab has reinforcement in the form of a mesh

or individual bars.

§ Reinforcement in the waffle slab is two-way.

§ Small beams are connected with main horizontal beams that

form a grid-like shape.

ALSO

READ: MINIMUM

SIZE OF CONCRETE SLAB, BEAM & COLUMN

DETAILS OF WAFFLE SLAB

§ A waffle slab construction is generally suitable for

flat areas.

§ The amount of concrete used in the waffle slab is less compared

to other types of slabs.

§ Waffle layers have good shrinkage resistance.

§ Waffle slab is a structural component that is hollow

from the top and has a grid-like structure at the bottom.

§ Waffle slab can be used for floor construction and

ceiling.

§ A flat slab cannot be built for a longer span and also

cracks can occur.

§ Waffle slab is a special type of slab that is mainly

built for a long time and is resistant to cracking and sagging.

WAFFLE SLAB CONSTRUCTION

§ The waffle slab construction is done in three ways.

a)

In situ construction,

b) Precast Construction

c)

Prefabricated construction.

§ As per the design and the size required waffle slab is

cast in site

§ In the construction of the precast waffle slab, the slab

panels are casted elsewhere and joined to the reinforcement.

§ In prefabrication of waffle slab, reinforcement is

provided on the slab panels during casting.

§ Compared to the other two slab types, the construction

cost of the slab made of prefabricated is higher.

§ Waffle slab construction is generally preferred for gaps

of more than 12 meters.

§ Waffle slab construction requires approximately 30% less

concrete and 20% less reinforcement.

ALSO

READ: Know

How To Calculate Loads On Column, Beam, And Slab

If you find

This information helpful please share it.

Thanks! For reading the article.

No comments:

Post a Comment