A

structure is made up of many connecting building elements such as walls, beams,

columns, foundations, slabs. Of these, the slab is the most important. This

allows other parts of the building elements to withstand different loads. There

are different types of slabs in construction. But in this article we have

discussed in detail the types of concrete slabs.

What is a Slab in Construction?

A

slab is a structural element that is made of concrete, which is used to create

flat horizontal surfaces such as floors, roofing floors and roofs. A slab is

usually several inches thick typically between 100 and 500 mm thick and is

supported by beams, columns, walls or floor.

TYPES OF CONCRETE SLAB USED IN

CONSTRUCTION

1. FLAT SLAB

2. CONVENTIONAL SLAB

3. HOLLOW CORE RIBBED SLAB OR HOLLOW CORE SLAB

4. HARDY SLAB

5. WAFFLE SLAB

6. SUNKEN SLAB

9. COMPOSITE SLAB

10. LOW ROOF SLAB

11. PROJECTED SLAB

12. WAIST SLAB

1.

FLAT SLAB

Flat

slab is also known as beam-less slab because it is supported directly by columns or

caps. Here, the loads are transferred directly to the columns.

The function of this type of slab is to provide a plain ceiling surface, which will

give the best diffusion of light. They are commonly used in hotels, parking

lots, commercial buildings or places where beam projections are not suitable

for height controls or even aesthetics view.

ALSO READ: What

Is Flat Slab? | Application Of Flat Slabs | Advantages And Disadvantages Of

Flat Slab

2.

CONVENTIONAL SLAB

A

slab supported by beams and columns is called a conventional slab or regular

slab. In these types, the thickness of the slab is small, while the depth of

the beam is large and it is transferred to the load-bearing beams and then to

the columns. This requires more formwork compared to the flat slab. It is not

necessary to provide column caps on the regular type slab.

ALSO READ: What Is

Conventional Slab | Types | Advantages | Disadvantages

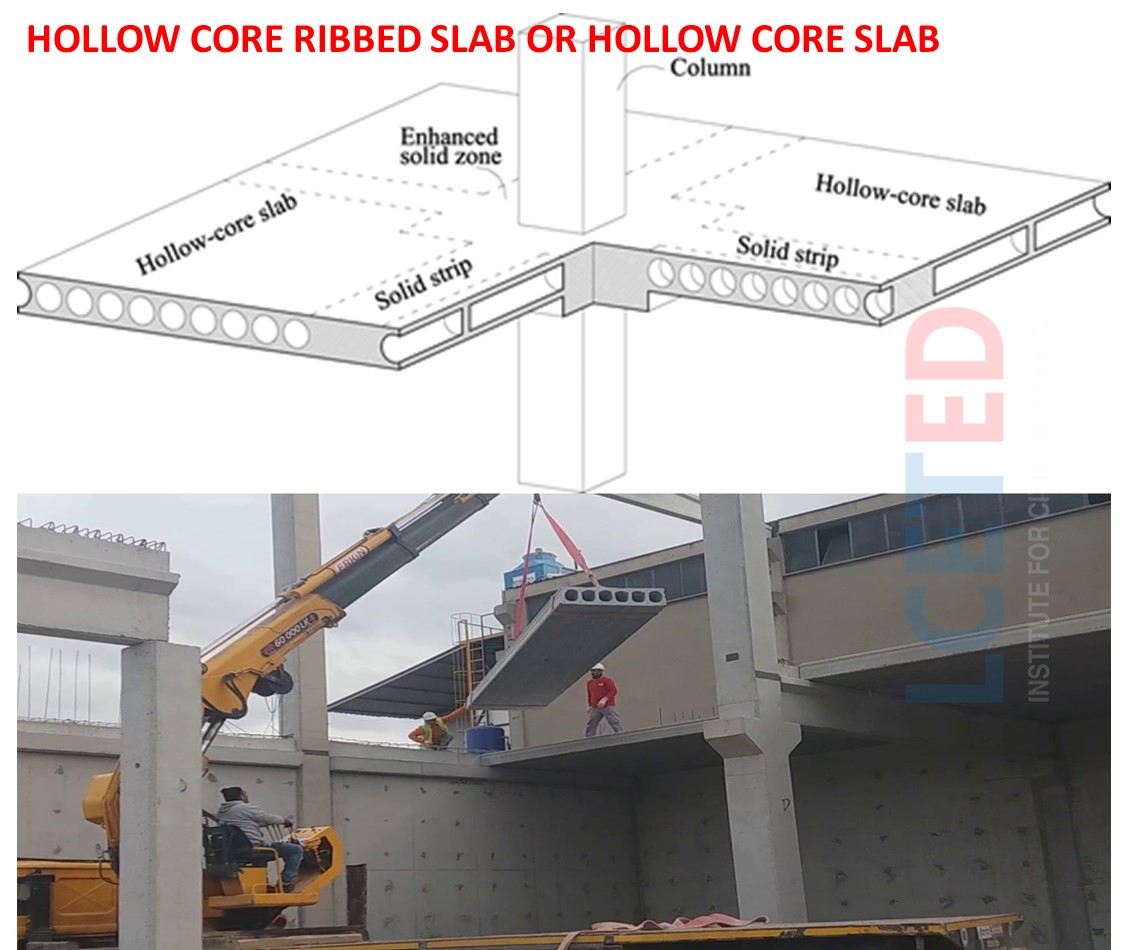

3.

HOLLOW CORE RIBBED SLAB OR HOLLOW CORE SLAB

It

name derived from the cores or voids that run through the units. The cores can

act as service pipes and will undoubtedly reduce the self-weight of the slabs

and increase structural efficiency. Cores also have the advantage of stability

by reducing the amount of material used.

4.

HARDY SLAB

This

type of slab is built with hardy bricks which is made of hollow bricks and

concrete. These bricks are used to fill thick slab areas, which saves the

amount of concrete, thus reducing the slab's weight. These types of slab are

commonly found in Dubai and China. This slab is used in areas where the

temperature is very high. The thickness of the slab is increased to withstand

the temperature from above the slab. The heat coming from the walls is

counteracted by using special bricks that contain thermocoles.

ALSO READ: What

Is Hardy Slab | Types | Application | Advantages | Disadvantages

5.

WAFFLE SLAB

Waffle

slab is a also called grid slabs. It is a reinforced concrete roof or floor with a square grid with deep sides. This type of slab is mainly used for good picture

viewing and installation of artificial lighting at the entrances of hotels, malls and restaurants.

This

is a type of slab where you can see that there is a hallow hole in the slab

when the formwork is removed. PVC sheets (pieces) are first placed on the

shutter, then reinforcement is provided between the pieces and a steel mesh is

provided above the pod, which is then filled with concrete. After the concrete

sets, the formwork is removed and the PVC pieces are not removed. This creates

a hollow hole in which a hole is closed at one end.

This

type slab is mainly used for industrial and commercial buildings, while wood

and metal waffle slabs are used on many construction sites.

ALSO READ: What

Is Waffle Slab? | Types | Advantages And Disadvantages

6.

SUNKEN SLAB

This

type slab used below the washrooms to cover sewer pipes or WC pipes or other

equipment is called a sunken slab. Care should be taken to avoid leakage

problems as the water pipes are hidden below the ground.

Proper

waterproofing and treatment of the slab provided to prevent leakage or

moisture. After sending the sewer pipes in the slab, the slab is filled with

broken bricks or coal or suitable lightweight material.

The

slab that is provided below the normal level of the floor at a depth of 200mm

to 300mm and filled with pieces of broken brick is called a sunken slab.

or

The slab that is provided above the normal floor level at a height of 200mm to 300mm and filled with coal or pieces of broken bricks called the sunken slab.

7. PRESTRESSED CONCRETE SLAB

a)

Pre-Tensioned Slab:

The

steel tensioned in slab before placing the concrete is called the pre-tensioned

slab. The slab has the same features of post-tension.

b)

Post-Tensioned Slab:

The

slab in which the steel cables or tendons are tensioned after concreting is

called the post-tensioned slab. Reinforcement is provided to resist

compression. In this slab, the reinforcement is replaced with steel cables /

tendons.

This type slabs break the natural

weakness of the concrete in tension and makes better use of its strength in

compression.

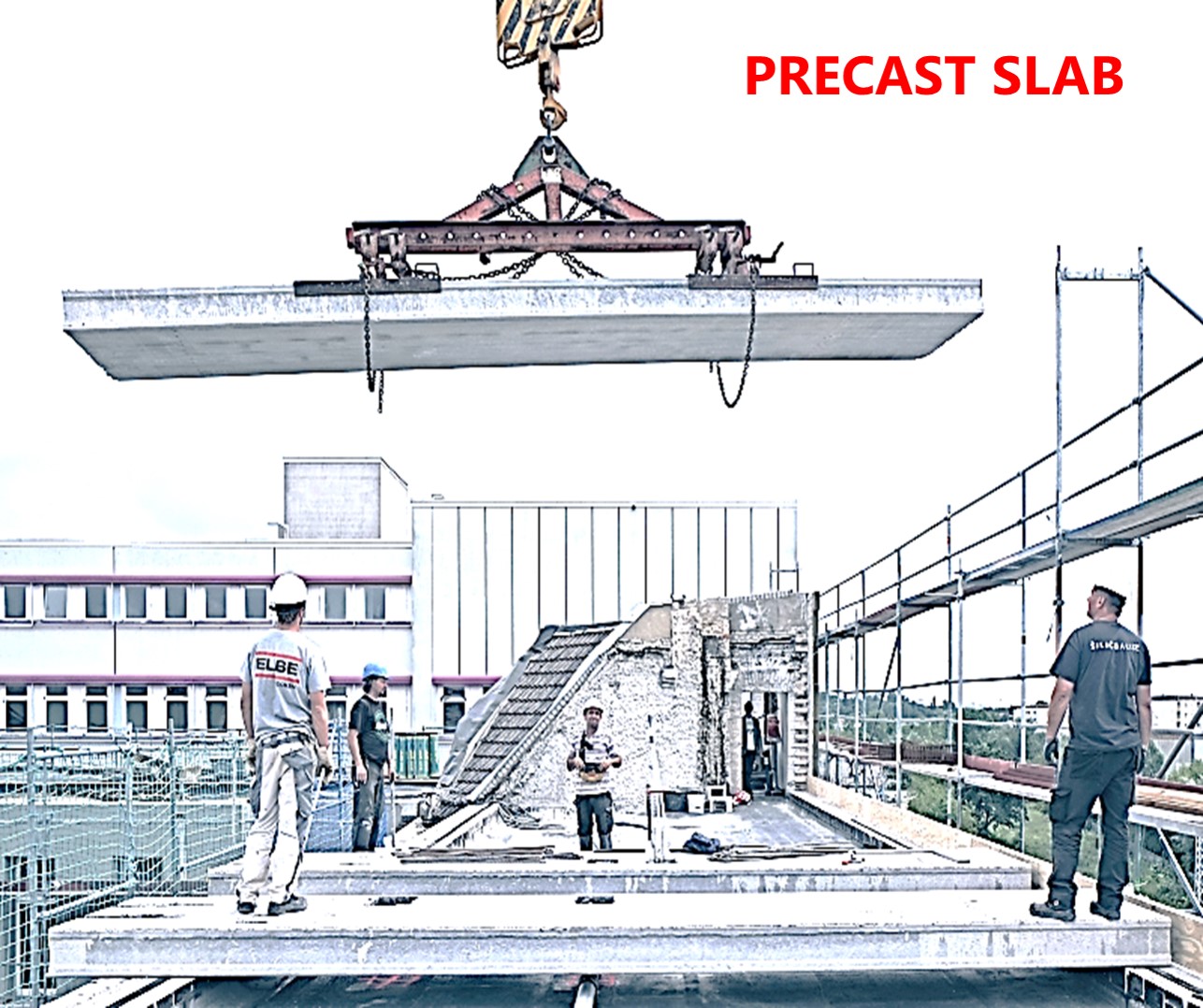

8. PRECAST SLAB

Precast concrete slabs are embedded in fabrication plants and cured, after which they are supplied for erection. The greatest advantage of precast concrete slabs is that they are manufactured in the plant, which increases their performance and achieves high-quality control over concrete slabs on site

Additionally,

precast concrete slabs can be found to be about 24% cheaper than cast-in-place

concrete slabs. Even if you spend more on assembly, you save a lot on formwork.

The

most commonly used precast slab types are channel and double T types.

9.

COMPOSITE SLAB

Typically, it is built on

reinforced concrete castings on top of a profile steel base. During the

construction phase the decking acts as a working area and formwork, and also

acts as an external reinforcement during the life of the slab.

10.

LOW ROOF SLAB

The

slab provided above the door for storage is called a low ceiling (roof) slab.

This type of slab closes at all ends and opens at one end. This slab is just

below the actual slab and above door and window level. This type of concrete

slabs are used in homes.

11.

PROJECTED SLAB

A

slab that is fixed on one side and free on the other is called a projected slab

or cantilever slab. These types of slab are usually built in hotels,

universities, function halls, etc to use that area for picking or dropping up

zone and for unloading and loading area. This is one of the types of concrete

slabs.

12.

WAIST SLAB

The

Waist Slab is

nothing more than a normal slab with some inclination angle between the two

supports. (Mainly used on RCC stairs).

The

Waist Slab rests

from the beam to the beam and the main stair reinforcement steel goes up to the

middle of the resting beam. The thickness of the waist slab depends on the

length of the stair flow. Usually the thickness is 5 ″ or 6 of.

The Waist

Slab

has three types of reinforcements;

·

Main steel

·

Distribution steel

·

Extra top.

Function of Slab

01. It gives a flat surface

02. To support loads

03. It gives heat fire, and

sound insulator

04. The top layer becomes

the roof for storey below it

05. The space between the ceiling

and slab can be used to place building applications

Effective Span of the RCC Slab

The effective span of slab should be lesser of the two

L = Center to centre distance between

the support

L = Clearspan + d (effective depth of

slab)

Minimum Thickness of Concrete Slab

The slab thickness is decided based on length of span to depth ratio as given in IS 456: 2000.

Must

read: What is

Lintel? | Types of Lintel | Uses | lintel length Calculation | lintel bearing

Must

read: Hardy

Slab Calculation | Quantity Survey | Volume Of Concrete & Area Of

Shuttering

Must

read: Waffle

Slab Calculation | Quantity Survey | Volume Of Concrete & Area Of

Shuttering

Must

read: Pitch

Roof Calculation | Quantity Survey | Volume Of Concrete & Area Of

Shuttering

Must

read: Semi‐Round

Stair‐Case Calculation | Quantity Survey | Volume Of Concrete & Area Of

Shuttering

Must

read: Lift-Pit

Calculation | Quantity Survey | Volume Of Concrete And Area Of Shuttering

Must

read: Ramp

Calculation | Quantity Survey | Volume Of Concrete & Area Of Shuttering

Must read: Dome Slab Calculation | Quantity Survey | Volume Of Concrete | Area Of Shuttering

No comments:

Post a Comment